Bedding

From mattress insulators to inner panels, dust covers, and quilt backers, Conwed™ Netting delivers essential reinforcement, durability, and stability features.

From mattress insulators to inner panels, dust covers, and quilt backers, our Conwed™ Netting for bedding applications delivers essential reinforcement, durability, and stability features. Compared to other alternatives, our product portfolio is lightweight, non-corrosive, rust-proof, stretch-resistant, chemically inert, and compatible with other materials. Whether you use our nettings independently or combine them with other substrates to form a composite, we have a solution for you.

Netting Insulators

A bedding insulator is a product situated on top of an innerspring to prevent fill layers (fiber pad, nonwovens, foam, and shoddy pad) from pocketing or falling into the coils. Conwed™ Plastic Netting acts as the mesh insulating element in bedding products.

Our netting insulators provide superior strength, durability, and superb pocketing protection. Mattress manufacturers use Conwed™ Netting to replace rope, wire, and other insulators.

Composites for Bedding Applications

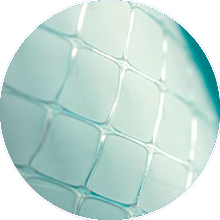

Conwed™ Lamination Composite is a finished composite of a thermally activated adhesive net and a nonwoven. Conwed™ Heat Activated Netting strengthens the nonwoven material, minimizing stretch and instability. The resulting composite offers the performance of much heavier nonwovens and ensures consistency, appearance, and strength to meet strict product requirements.

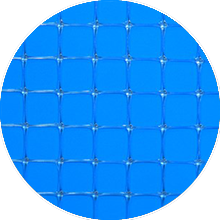

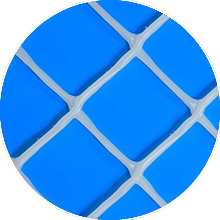

Conwed™ Netting Insulator

Conwed™ Netting Insulator is the premier netting insulator with 20 times more cross strands than wire and rope insulators. It has exceptional strength, maintains firmness, and provides superior pocketing protection.

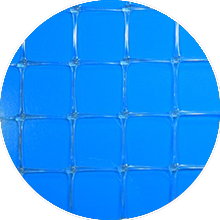

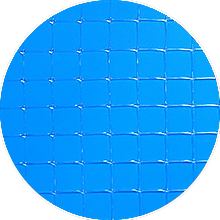

Conwed™ Netting Insulator 300

Conwed™ Netting Insulator 300 is a durable, lightweight netting insulator suitable for many types of bedding construction, especially those with lower coil counts. Its heavy-duty open mesh provides quiet, uniform insulation and is used to create and maintain a plush feel.

Conwed™ Netting Insulator 150

Conwed™ Netting Insulator 150 is our most economical netting insulator with features similar to those of the Conwed™ Netting Insulator 300. It is the perfect alternative for institutional bedding requirements because it provides quiet insulation, minimizes pocketing, and prevents fill materials from falling through.

Conwed™ Netting for Mattresses

Conwed™ Netting for Mattresses is a versatile, rugged configuration that provides consistent support over padding and fills. It is designed for premium mattresses to increase lumbar support in crown cuts while helping maximize firmness over time.

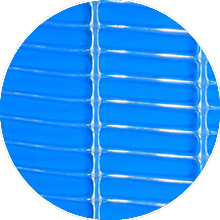

Conwed™ Netting for Quilt Backing

Conwed™ Netting for Quilt Backing is our strong, lightweight, stretch-resistant netting backer for mattresses. It adds excellent stability and tensile strength to the quilting on premium mattresses. Quilt backing netting is used to hold the stitch in the quilting process when the cover, ticking (fabric covering mattresses and foundations), foam, and other fibers are sewn together. A secondary function is to provide a final layer of insulation to protect the ticking from wear. Our netting and nonwoven composite is the ideal backer component for ticker quilt configurations. It delivers no-stretch functionalities with outstanding tear resistance. It maintains a high-loft, tailored look while being a more economical alternative to heavier nonwoven fabrics needed to attain similar tensile strength.

Conwed™ Netting for False Pads

In the bedding industry, fales pads are compressed cotton felt stitched together to retain the compression better. Conwed™ Netting for False Pads netting reinforces pads in mattresses by holding stitches in place. This durable, strong, lightweight netting is stitched to cotton padding to increase tensile strength and stability. It can also be stitched to synthetic materials as additional reinforcement.

Conwed™ Heat Activated Netting

Conwed™ Heat Activated Reinforcement Netting combines two or more substrates into a single, improved composite structure. The adhesive properties are built into the netting to bond and strengthen various materials. It is a co-extruded plastic netting with one or more layers of adhesive components.