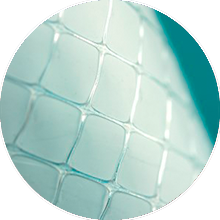

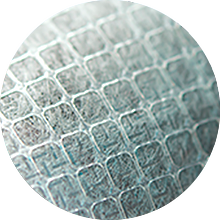

Co-Extrusion Netting

Explore our proprietary netting technology to build superior composites.

Co-Extrusion is a multi-layer extruded netting that can subsequently be oriented where different polymers can form different layers on the same configuration. Co-extrusion netting is a square netting construction, and Conwed can build netting with A/B, A/B/A, and A/B/C layer combinations.

Customers can benefit from the flexibility co-extrusion products provide in high-performance composites. Conwed™ Co-extruded Netting can be incorporated with nonwoven, foam, paper, film, membrane, tissue, and other fabrics to become part of composites used in various industrial and consumer applications. By using co-extrusion netting with adhesive layers, manufacturers and converters may eliminate adhesive steps in their manufacturing and converting processes for specific product applications.

Extruded netting can be found in composites for automotive, apparel, cleaning, medical, building and construction, wipes, and other disposable industrial and consumer products.