Diamond Netting

High‑strength, bi‑planar diamond mesh engineered for superior protection, separation, and customization.

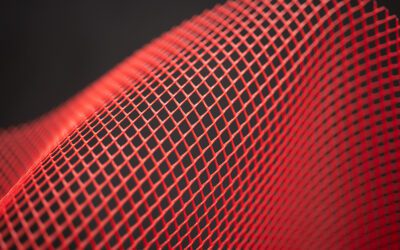

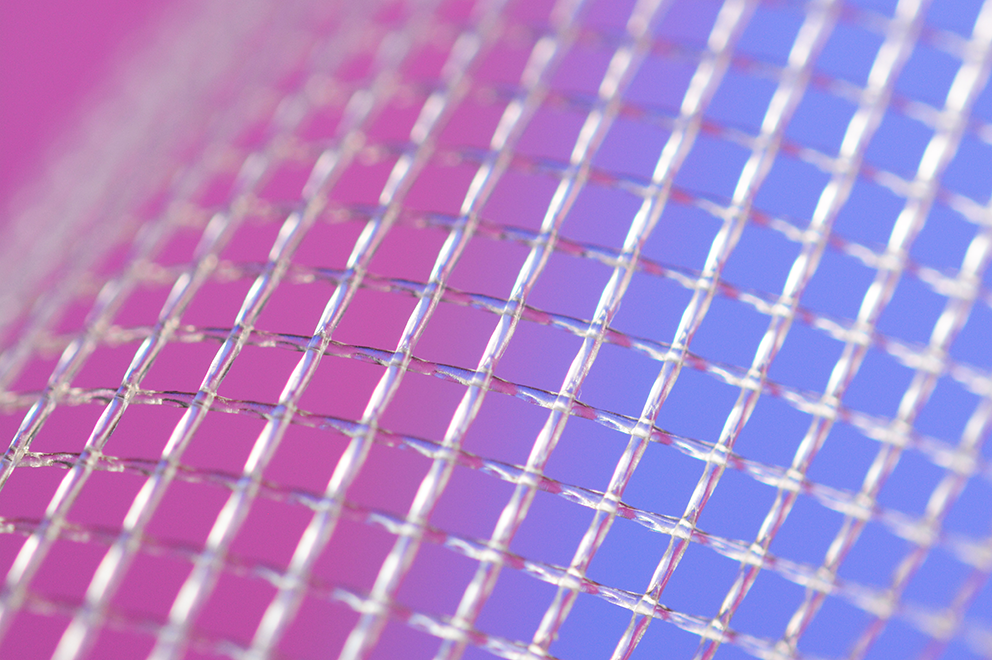

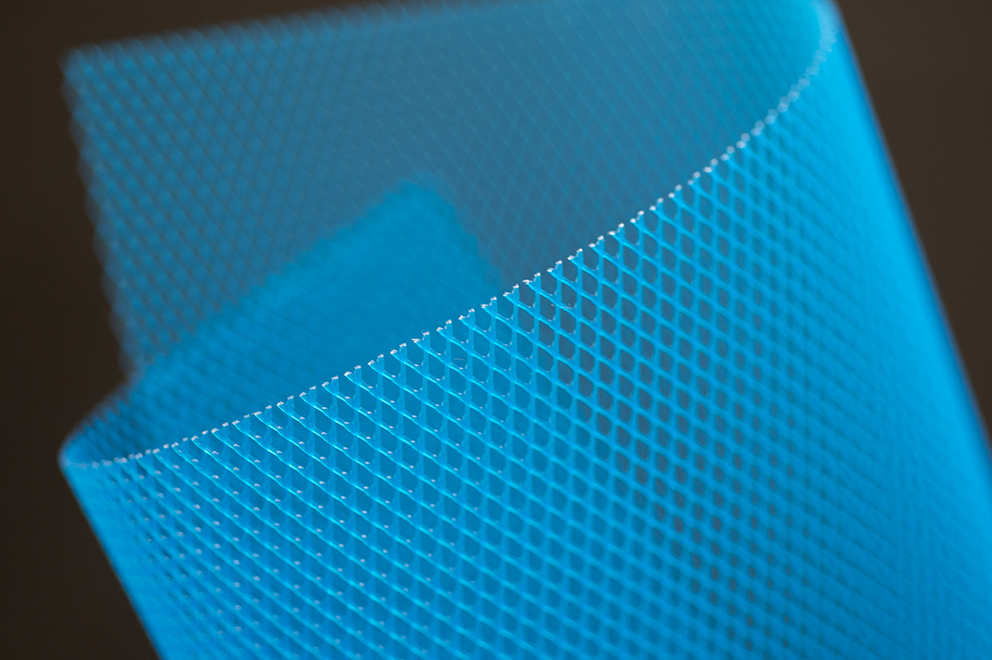

Extruded diamond netting, or bi-planar netting, is extruded netting with a diamond-shaped configuration. One major difference between square and diamond netting is that diamond netting has a set of strands on top of the others in opposite directions and not on the same level as found on square netting. The strands appear to run diagonally in both Machine and Cross Directions to form the diamond mesh design.

Conwed™ Extruded Diamond Netting is also used in tightly-spaced pleat packs for superior pleat separation. We can customize mesh sizes, thicknesses, weights, tensile strength, colors, angles, and chemical formulations to meet our customers’ requirements.

Extruded diamond, bi-planar mesh netting with bonded strand intersections

Conwed™ Diamond Netting is an extruded, diamond, bi-planar mesh netting with bonded strand intersections, widely utilized in many industries. Many industrial applications benefit from diverse customization options. Diamond netting can also be used for packaging, containment, construction, and parts protection.

Performance

-

- Separation in in Building & Construction for Pavernet and Fencing

- Containment in Agriculture for Aquaculture Shellfish Cages

- Protection in Building and Construction for Pipeline Protection, Fencing, AC Hall Guards

- Protection in Packaging for Produce Stacking and Meat Case Liners where drainage is required

- Consistent Material Flow in Resin Infusion for Wind Turbine Blades, Aerospace, and Automotive Composite Manufacuring

Features

- Industry-leading diamond netting technology

- Improved process of extruding through counter-rotating die heads

- New resins, varied strand count, and cross-sections

- Full range of strand angles, offering customers different looks, feels, strengths

- Added value for niche applications with additives like UV stabilizers, antioxidants, flame retardants, antimicrobials, color and slip agents

- Limitless customization

- High-strength

Variations

- Extruded Cage & Sleeves

- Extruded Diamond Netting

- Parts Protection Netting

- Resin Infusion

Benefits

- Partner with us to develop a custom solution for your unique process

- Lightweight, protective netting capable of supporting heavy products

- Will not corrode in intense sunlight or saltwater environments

- Extruded material that will not shed, fray, or unravel

Strand Geometry Options

- Symmetrical: both sets of strands are at an angle to the machine’s direction

- Asymmetrical: strands are at an angle to the machine direction but are different in number and size

- Non-symmetrical: one set of strands runs in the machine direction while the other runs at a customer angle.

Naconet™ – Compostable Netting

- Made from renewable, bio-based materials

- Industrial Compostable

- Breaks down into CO₂, water, and biomass – no microplastics

- Non-toxic and safe for soil, water, plants, animals, and food contact

- Compatible with standard netting and packaging equipment

- Manufactured in the USA and Europe for global availability and reduced emissions

Conwed™ Extruded Diamond Netting Products

Naltex™ Extruded Diamond Netting

Vexar™ Protective Sleeves

Vexar™ Header Bags

Naltex™ Flow Media

Naltex™ Paver Saving

Case Liners for Shipping, Display & Storage

Markets where Conwed™ Diamond Nettings are needed

Agriculture & Aquaculture

Netting for crop and animal protection, fencing, turf netting, hay bale netting, garden & nursery support products.

Composite Manufacturing

Flow media for resin infusion in turbine blade production, baghouse filters, pipeline protection, hydraulic oil, oil boom netting & wind energy.

Building & Construction

Netting solutions for roofing, pipeline protection & paver

Packaging

Ideal solution for packing, storing, and shipping food, beverage, candy, toys, crafts, decor, bulk items, equipment & electronics.

Parts Protection

Protect filter elements and other parts with our Naltex™ Sleeves

Filtration

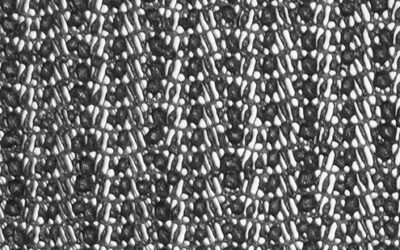

Feed Spacer for Liquid Filters and Reverse Osmosis, and Pleat Support for Filter Elements

Engineered netting for flow channels for air & liquid

Flow channels might not be the first thing that comes to mind when you think about advanced materials, but these engineered pathways are quietly enhancing applications across a wide range of industries. When combined with specialized netting materials, flow channels...

Christmas Tree Netting

We help contain, pack, and transport trees safely and securly. Optimal packaging with Conwed™ Transform your Christmas tree packaging processwith Conwed™ netting. Specifically designed to serveas a sleeve, our netting ensures optimal packaging—keeping each tree secure...

Bio-based & compostable netting – discover our sustainable packaging solution

Searching for a sustainable netting for packaging? Our bio-based, compostable nettings deliver unmatched reliability and eco-friendliness - allowing you to maximize efficiency while meeting your environmental goals – means, you’re not loosing any performance with our...

Prepare for the upcoming harvest season- Customized netting solutions for agriculture

Harvest season brings both opportunity and challenge for agricultural operations. While it represents the culmination of months of hard work, it also demands maximum efficiency to protect valuable crops and minimize losses. High-quality agricultural netting has...

Customizable grip liners for industrial and packaging

Versatile, durable, and reusable case and grip liners for shipping, storage, and product overwraps perfectly adapted to your needs. Our grip liners, available as standard grip liners (soft bubble foam) and air grip liners (thick and easy-to-position), offer secure...

Engineered netting solutions for divers applications in building and construction

Conwed's high-quality and versatile netting solutions are designed to enhance efficiency and performance in the building and construction industry. From reinforcing materials to creating energy-efficient composites, our high-quality netting enables manufacturers to...