Separation

Separation Netting Solutions for Filtration, Construction & Composites

From air and liquid filtration to rain screen walls and resin infusion processes, Conwed™ separation netting provides essential separation and flow functionality across industries. We have decades of experience helping manufacturers separate materials and control fluid flow effectively. Our customers incorporate Conwed netting as critical components in their end products to create needed gaps, channels, and support structures that boost performance. Whether the goal is filtering contaminants, draining moisture, or distributing resin, Conwed’s engineered netting ensures the right separation for optimal results.

Applications & Benefits of Conwed’s Separation Nettings

-

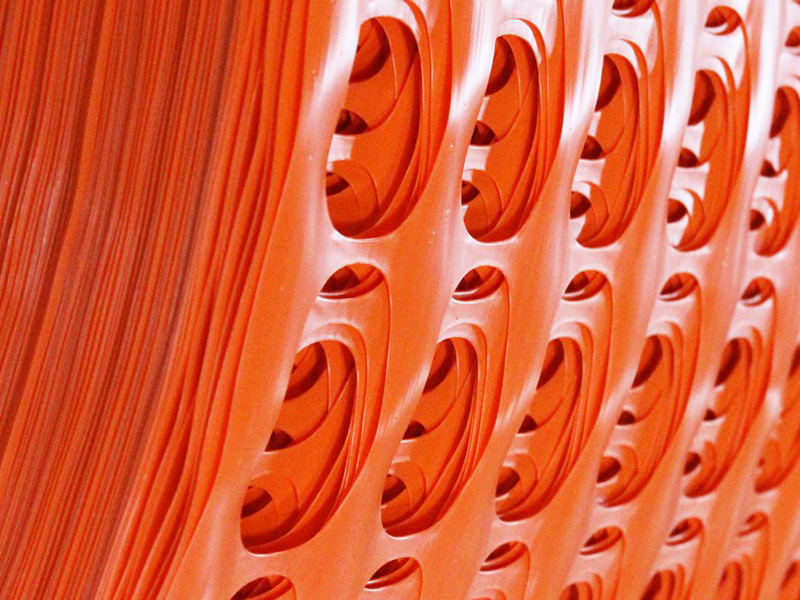

Air & Liquid Filtration: In filtration systems, plastic netting serves as pleat supports and feed spacers inside filter cartridges, maintaining open flow paths and preventing media collapse. By creating a uniform gap between filter layers, Conwed’s netting reduces pressure drop and ensures proper permeate flow and low turbidity in processes like water purification and industrial filtration. We also supply rigid extruded cylinder net tubes that act as durable cores in filters, adding structural support while maximizing open area for fluid passage. Result: filters that run efficiently, with longer life and consistent performance.

. -

Rain Screens & Building Envelopes: In construction, our separation netting is used in rain screen wall systems and house wraps as a drainage and ventilation layer. Placed between the exterior cladding and weather barrier, the polymer mesh maintains a critical air gap that allows water to drain away and moisture to evaporate. This prevents trapped water that could cause mold or damage, protecting the building structure. Conwed’s UV-stable plastic netting provides a lightweight, rot-proof spacer that is easy to install behind siding or masonry. The result is a healthier, longer-lasting wall – an effective rain screen that meets modern building codes for ventilation and drainage.

. -

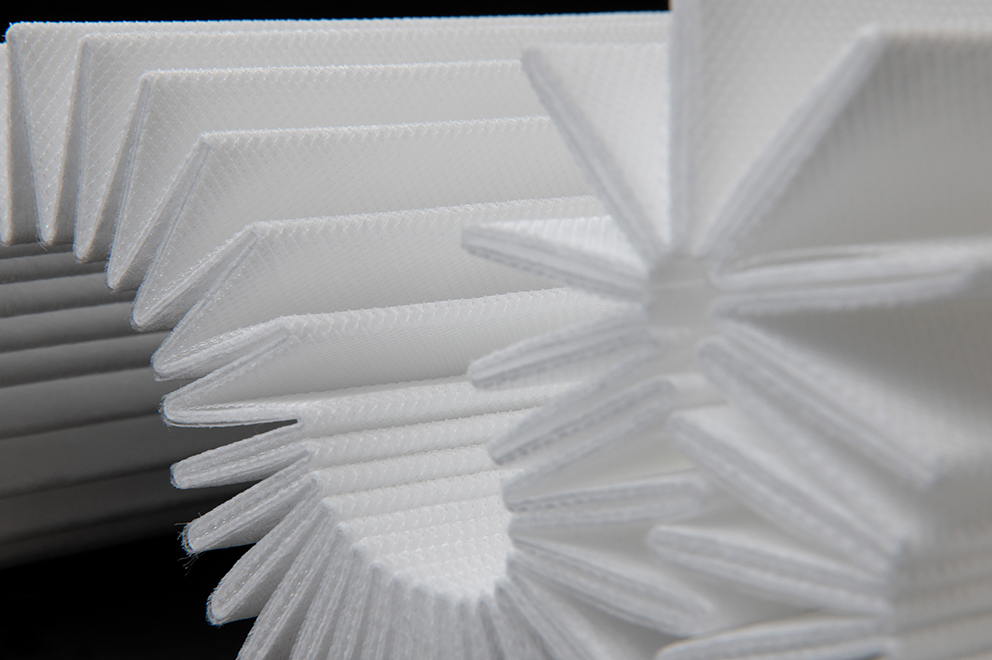

Resin Infusion for Composites: For composite manufacturing, Conwed™ Flow Media netting is a high-performance infusion mesh used in vacuum infusion processes (VARTM) for large parts like wind turbine blades, boat hulls, and aerospace components. It acts as a resin distribution medium, creating fast, uniform resin flow across the mold. Uniquely, Conwed’s flow media is specially engineered to retain up to 15% less resin than competing flow netting. This means manufacturers can impregnate fibers fully with significantly less excess resin, yielding material cost savings and lighter finished parts. The mesh’s bi-planar design also ensures complete wet-out with no dry spots, so the cured composites are strong and void-free. By speeding up resin infusion while minimizing waste, Conwed flow media helps composites producers achieve higher quality at lower cost.

Conwed’s Separation Netting Products

We offer a range of extruded plastic netting products tailored to these applications, each designed for strength, open area, and compatibility with your process:

.

-

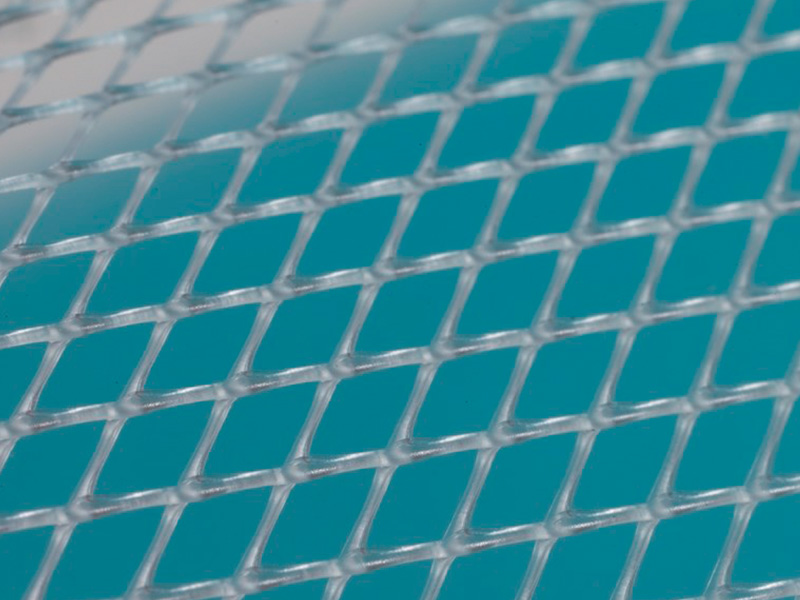

Extruded Diamond Netting: A bi-planar net with diamond-shaped apertures (e.g. our Naltex™-type netting). Diamond net is used as feed spacer mesh in filters and as flow media in infusion, thanks to its inherent channeling geometry. It provides turbulence and spacing in spiral wound membrane filters (reverse osmosis), enhancing flow distribution and reducing fouling. Made from polymers like polypropylene or nylon, it withstands chemicals and temperatures in industrial filtration.

. -

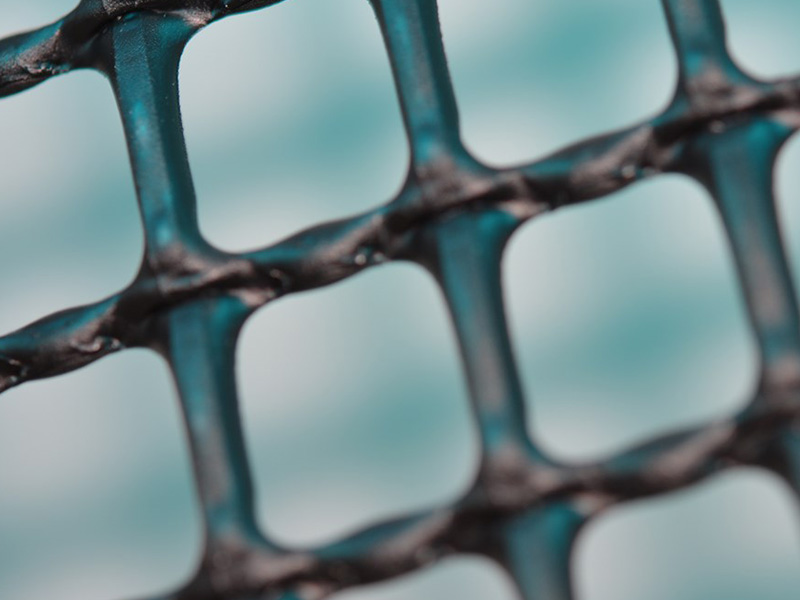

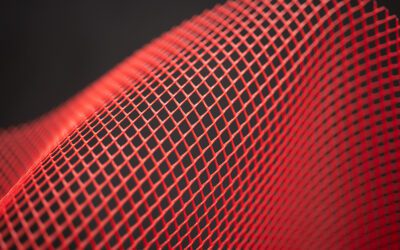

Extruded Square Netting: A rigid net with square apertures, produced in a continuous extrusion process for integral joint strength. Square netting is ideal for protective separation and support – it’s found in everything from automotive parts protection to infrastructure and building materials as a strong yet lightweight containment net. It can reinforce products (e.g. holding insulation or foam in place) while allowing airflow or drainage. We offer various resin formulations (PE, PP, etc.) to meet specific requirements for strength, flexibility, or UV-resistance.

. -

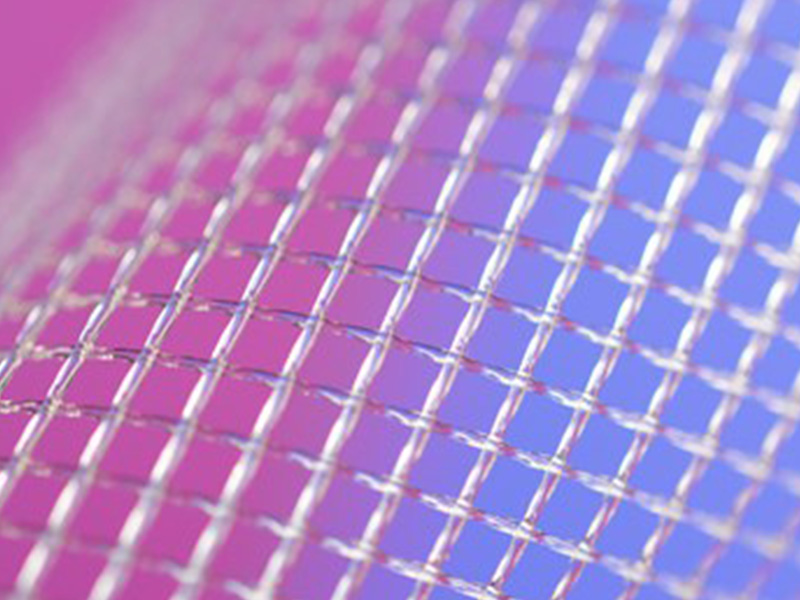

Flat Netting: A thinner, single-layer netting used when minimal thickness is needed for separation. Flat netting provides a smooth, open mesh spacer in layered products like absorbent pads, battery separators, or anywhere a slim gap is required between materials. Its high open area facilitates fluid or air passage in a compact form factor.

. -

Flow Media & Netting Tubes: For specialized needs, we provide Flow Media nets (with optimized flow channels and flexible edges for easy lay-up in composite molds) and extruded cylindrical net tubes in various diameters. The flow media is used as described above for resin infusion, available in rolls and custom sizes. Our cylinder tubes serve as filter cores or protective sleeves, offering 360° support to filter elements and preventing pleat deformation or damage during operation. These tubes and sleeves are made to fit standard cartridge dimensions or can be customized to your specifications.

Conwed ensures each netting solution is engineered for its application. All our products feature consistent openings and robust bonding, resulting in reliable performance in high-pressure or high-flow environments. We work closely with clients to select the right resin and mesh geometry that will meet their needs for strength, flexibility, and compatibility (e.g. food-grade materials for beverage filters, UV-stable netting for outdoor use, etc.). By leveraging our deep expertise in material science and extrusion technology, we deliver netting components that improve your product’s efficiency and longevity.

Why Choose Conwed Netting for Separation?

-

- Engineered for Performance

Our netting is not just plastic mesh – it’s precision-engineered to meet demanding specifications. Whether you need high-flow filtration support, moisture-draining rain screen layers, or resin-saving flow media, Conwed netting is designed to optimize your process. - Material Efficiency & Cost Savings

Our Flow Media retains up to 15% less resin than leading alternatives, helping composite manufacturers reduce raw material usage and lower production costs – without compromising quality. - Customization & Flexibility

We offer a wide range of mesh geometries, thicknesses, and resin types (including PP, PE, Nylon, and specialty polymers) to match your exact application needs. From flat netting to extruded tubes and diamond mesh, we tailor our products to your performance and regulatory requirements. - Global Manufacturing & Quality Assurance

With ISO 9001-certified facilities and a global supply network, we ensure consistent quality, fast lead times, and responsive support – wherever you are. - Sustainability Commitment

Our netting solutions are designed with efficiency and longevity in mind, helping reduce waste and extend product life. We work with customers to explore recyclable materials and sustainable design options.

- Engineered for Performance

Markets where Separation Nettings are needed

Filtration

Conwed’s separation netting is used in air and liquid filtration systems, acting as pleat supports, feed spacers, and protective layers in HVAC, water purification, and industrial filters.

Building & Construction

Used in rain screens and house wraps to create drainage cavities and air gaps, improving moisture control and thermal performance in building envelopes.

Conwed’s Netting Products for Separation

Engineered netting for flow channels for air & liquid

Flow channels might not be the first thing that comes to mind when you think about advanced materials, but these engineered pathways are quietly enhancing applications across a wide range of industries. When combined with specialized netting materials, flow channels...

Bio-based & compostable netting – discover our sustainable packaging solution

Searching for a sustainable netting for packaging? Our bio-based, compostable nettings deliver unmatched reliability and eco-friendliness - allowing you to maximize efficiency while meeting your environmental goals – means, you’re not loosing any performance with our...

Closing the loop for a circular economy – PCR netting for packaging

Did you know we offer a netting made from up to 30% post-consumer- recycled plastics? Close the loop with Conwed’s post-consumer-recycled plastic netting. Get the same strength and reliability you trust, while reducing your product carbon footprint and meeting EPR...

Lightweight, durable, and cost-effective plastic fencing for every project

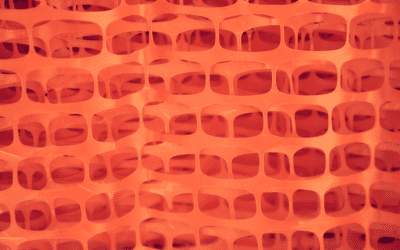

When planning events or managing construction sites, safety and clear demarcation are non-negotiable priorities. That's where our plastic fencing solutions come in. Unlike traditional metal barriers that are heavy, expensive, and difficult to transport, our plastic...

Durable Protection for Paving Stones in Storage and Transit

Every construction professional and homeowner knows that the beauty and functionality of high-quality paving, concrete, and architectural blocks come at a cost. A well-crafted paving design is a reflection of precision, durability, and aesthetic appeal. But the effort...

Lightweight & durable netting for fencing

Looking for durable, lightweight, and cost-effective fencing solutions? Whether you need fencing for construction-site safety, snow management, or crowd control at public events, our plastic netting is engineered to meet your unique requirements with precision and...