Reinforcement

Reinforcement Netting Solutions for Stronger, Lighter Products

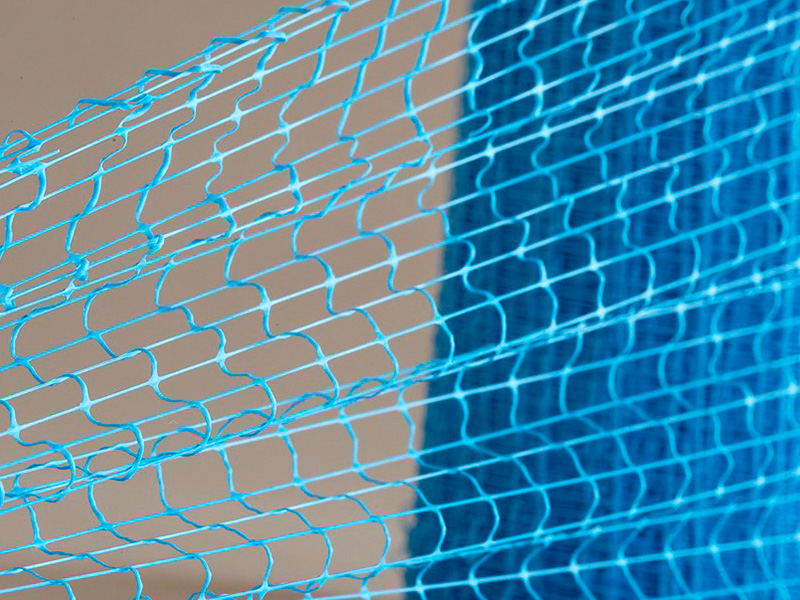

When it comes to reinforcement netting, Conwed delivers superior strength in a lightweight form. Our advanced netting solutions add durability and support to your products without excessive weight, helping them perform under the toughest conditions.

.

Built for High-Strength & Low Weight

Conwed™ reinforcement netting boosts tensile strength in everything from heavy-duty packaging to technical composites. By integrating our netting, manufacturers can reduce overall product weight by up to 30% without sacrificing strength. This strength-to-weight advantage means your bags, films, and composites withstand stress and wear while remaining lightweight and cost-efficient.

.

Versatile Applications Across Industries that Require Reinforcement

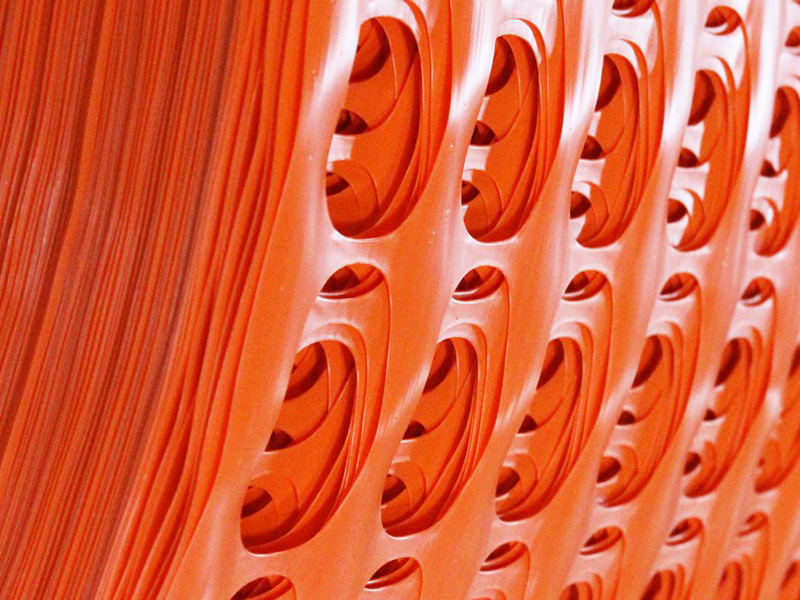

- Industrial Packaging & Bags: Reinforce paper and plastic bags (e.g. pet food sacks) to prevent tears and bursting. The open mesh design adds strength while keeping packaging flexible.

- Nonwovens & Textiles: Integrate netting into medical wipes, cleaning pads, and hygiene products for improved tear resistance and product integrity. Netting adds strength inside nonwoven composites without adding bulk.

- Building & Construction: From house wrap laminates to roofing underlayments, our nets serve as an alternative to traditional scrims, imparting high tensile reinforcement in construction materials. They remain dimensionally stable even under temperature changes, ensuring durability in installations.

- Bedding & Furniture: Enhance mattress cushioning and furniture pads. A lightweight reinforcement mesh layer prevents foam and fiber fill from shifting or sagging, extending the life of cushions (e.g., carpet cushion reinforcement for padding stability).

- Agriculture & Turf: Strengthen turf rolls and sod with netting that allows roots to interlace, yielding thicker sod and more frequent harvests (as seen with competitors’ turf nets). Our netting also wraps and protects produce, letting air circulate to keep food fresh during transport.

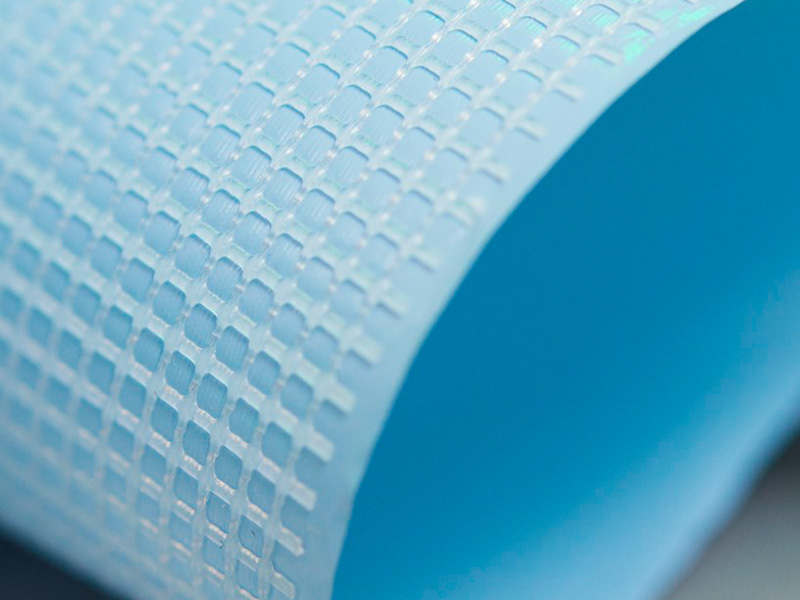

Innovative Co-Extrusion Technology

Conwed’s proprietary co-extruded netting brings multi-layer strength in one step. Different polymer layers can be combined in a single net structure, allowing built-in adhesive properties or varied material characteristics. This means our netting can bond directly to fabrics, films, foams, or paper in your production process – potentially eliminating separate adhesive steps and simplifying manufacturing. For example, a co-extruded net with an adhesive layer can fuse to a paper or film substrate during lamination, saving time and cost. We continuously push the limits of this technology to customize the strength-to-weight ratio for your specific needs.

Why Choose Conwed Netting for Reinforcement?

-

- High Strength-to-Weight: Achieve the required product strength with minimal added material. Our nets offer exceptional tensile reinforcement without bulk.

- Durability: Engineered to perform under extreme conditions – heavy loads, abrasion, or heat – maintaining structure where other materials fail.

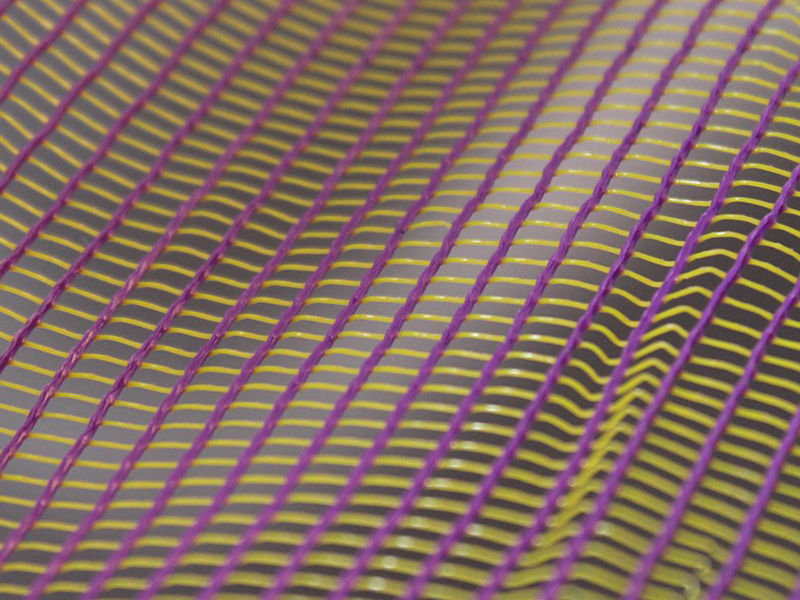

- Versatile & Customizable: Available in various configurations (square, bi-oriented, multilayer) to fit different applications. We tailor netting properties (material, mesh size, thickness) to meet your performance targets.

- Proven in Industry: Trusted across packaging, automotive, construction, and consumer goods sectors.

- Improved Efficiency: Incorporating our netting can streamline your production. Many customers find that using Conwed netting in laminates or composites speeds up processing and reduces material waste.

Markets where Reinforcement Nettings are needed

Elastomeric Netting in Therapeutic Bandages and Wraps

Therapeutic bandages and wraps are expected to deliver more than just support—they must combine comfort, durability, and breathability to meet the growing demands of modern healthcare. Achieving this balance requires materials that not only perform under stress but...

Heat-Activated Netting for Insulation Reinforcement: Strength and Efficiency in One Solution

Insulation materials are essential for energy efficiency and comfort in residential and commercial buildings. However, insulation products must withstand handling, installation, and long-term performance demands without compromising thermal properties. Reinforcement...

Adhesive, heat-activated netting for consumer & industrial wipes

Consumer and industrial wipes are essential for everyday cleaning tasks—from household dusting to heavy-duty scrubbing. These products must deliver strength, durability, and versatility while remaining cost-effective. Reinforcement netting is a game-changer, enabling...

Elastomeric Netting for Incontinence Products: Comfort and Functionality Redefined

Incontinence products are designed to provide security and comfort for users in sensitive situations. These products must combine flexibility, breathability, and durability to ensure confidence and ease of use. Elastomeric netting is a key innovation that enables...

Elastomeric Net in Baby Diapers and Training Pants

Modern baby diapers and training pants are more than just hygiene products—they are engineered for comfort, flexibility, and reliability. Parents expect products that move naturally with their child, prevent leaks, and feel soft against the skin. To achieve this,...

Net as a Game-Changer in Cleaning Products

The global nonwovens industry is booming, fueled by the rapid growth of disposable cleaning products. From household wipes to industrial scrubbers, consumers expect convenience, versatility, and performance. Conwed netting introduces technical advantages that...