Protective Sleeves

Flexible solutions for packaging, handling, and processing applications.

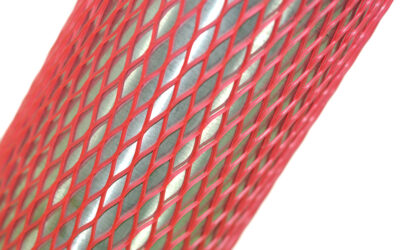

Conwed offers a complete line of Naltex™ and Vexar™ Protective Mesh Sleeves for various industrial applications. Our protective sleeves wrap around virtually any shape and surface type. They offer a strong yet flexible synthetic layer for optimal storage, transportation, and handling. From bulk packaging and high-pressure cylinders to glass, metal, plastic, auto, and industrial parts, Naltex™ and Vexar™ Protective Netting Sleeves help reduce potential wear and damage. They protect corners and edges and shield finishing, coating, and painting features in hundreds of finished products.

Available in a wide range of resins, colors, thicknesses, pre-cut sizes, and bulk roll stocks, Vexar protective mesh sleeves are an ideal alternative to safeguard your most valuable products.

Protective Mesh and Netting Sleeves can be used for:

- Parts separator

- Cylinder protection

- Bulk packaging protection

- Electroplating bundling

- Furniture protectio

- Pipe protection

- Wine and liquor bottle protection

- Nylon separation grids

- Metal parts protection

- Spring silencers

Everything You Need to Know About Conwed’s Protective Sleeves & Packaging Solutions

What are Conwed’s protective sleeves and what do they do?

Conwed’s protective sleeves are flexible plastic mesh nettings (sold under our Naltex™ and Vexar™ brands) designed to wrap around products of virtually any shape or size. They form a strong, elastic protective layer around an item to cushion it during storage, shipping, and handling, preventing scratches, chipping, or other damage.

By cradling edges and surfaces, the mesh sleeves reduce wear and protect finishes, coatings, and painted parts so that products arrive in pristine condition.

What types of items or applications are Conwed’s protective sleeves used for?

Protective mesh sleeves have very broad uses across industries. They are commonly used wherever parts or products need surface protection or separation during transit and storage. For example, Conwed sleeves serve as:

- Parts Separators: Placing mesh sleeves between or around components to keep them from touching and abrading each other (useful in bins of metal or plastic parts).

- Cylinder Protectors: Covering high-pressure cylinders or gas tanks with a sleeve to prevent dents and paint chipping on the cylinder surface.

- Bulk Packaging/Bundling: Securing multiple items together in a crate or bundle. Sleeves can hold irregular-shaped parts in place or bundle pieces (even used for electroplating racks to separate parts during metal finishing).

- Pipe and Rod Protection: Sliding over pipes, tubing, rods, or shafts to guard edges and threads from damage during handling.

- Bottle and Glass Protection: Used as wine or liquor bottle sleeves and on glassware, providing a cushioned mesh layer that prevents glass-on-glass contact and breakage.

(They are even used in niche applications like furniture protection for polished furniture pieces, nylon grids for separating items in layers, or spring silencers to dampen noise in springs.)

What are the key protective sleeve products and their primary applications?

Conwed offers a range of protective mesh sleeve options to suit different needs. The table below summarizes our key sleeve types and their typical applications:

| Protective Sleeve Type | Primary Applications |

| Standard Mesh Sleeves (Naltex™) | General-purpose flexible sleeves for a wide range of parts and products. Commonly used as part separators and surface protectors for small-to-medium components (e.g. separating machined parts in a box)9. |

| Heavy-Duty Mesh Sleeves (Vexar™) | Thicker, robust sleeves designed for large or heavy items and sharp-edged parts. Often used for protecting cylinders, heavy machinery components, and bulk packed industrial parts where extra strength is needed10. |

| Cylinder & Pipe Sleeves | Tubular netting specifically sized for gas cylinders, pipes, and tubes, guarding their surfaces and ends from impact and abrasion during transport11. |

| Bottle Protection Sleeves | Mesh sleeves for glass bottles and fragile containers (e.g. wine or chemical bottles) to prevent contact, cracks, and surface damage. They gently cushion each bottle and are breathable to avoid condensation12. |

| Bulk/Bundling Net Sleeves | Versatile nets used to bundle irregularly shaped items or multiple pieces together for shipping or processing (such as holding parts during electroplating or coating). Ensure items stay separated and secure in bulk packaging13. |

What are the benefits of using Conwed’s protective netting sleeves?

Manufacturers choose our protective sleeves because they solve many packaging challenges:

- Flexible, All-Around Coverage: The netting stretches to conform to almost any shape – from delicate glassware to bulky machine parts – creating a custom-fit buffer that prevents scratches, dents, and corner damage during handling. Unlike rigid packaging, a single sleeve size can often accommodate various part geometries.

- Ventilation & Moisture Control: The open mesh design allows air circulation and lets moisture or chemicals drain away. This ventilation reduces condensation and corrosion on metal surfaces and avoids trapping moisture (important for food items or any sensitive materials). Products are protected without sealing in humidity or odours.

- Lightweight & Cost-Efficient: Mesh sleeves add very little weight but are tough and quick to apply/remove, saving labor time. They often eliminate the need for bulky wraps, foam, or paper stuffing. By replacing disposable wrapping (like bubble wrap or foam), sleeves lower material costs and packing time while still keeping items secure.

- Reusable Durability: Made from resilient synthetic polymers, the sleeves withstand repeated use. They won’t tear easily and can be used through multiple manufacturing stages or shipping cycles. This durability means fewer replacements and a lower cost per use compared to single-use packaging.

- Chemical & UV Resistance: Conwed’s sleeves are engineered to resist oils, solvents, and UV exposure, so they hold up in harsh industrial environments. They won’t degrade or break down when exposed to lubricants, mild chemicals, or outdoor storage conditions.

- Versatile Across Industries: The same sleeve solution can serve many purposes – whether protecting auto parts, electronics, painted components, or even produce, the netting adapts to the task. This versatility simplifies inventory for manufacturers who have varied packaging needs.

Can Conwed’s protective sleeves be customized to different sizes or requirements?

Yes. We offer a wide range of sleeve options and can tailor them to your needs. Conwed protective sleeves come in various materials, sizes, and formats to ensure the right fit and performance for each application. We manufacture sleeves in an array of resin types, mesh diameters, thicknesses, and colors.

This means you can get, for example, a specific polymer for chemical resistance or a particular color-coded mesh to identify parts. Sleeves can be supplied pre-cut to exact lengths (for example, pre-cut pieces to slip over a certain part) or in bulk rolls that you can cut to size on-site. In short, you have full flexibility – from small, fine mesh sleeves for tiny components up to large-diameter, thick mesh sleeves for big industrial pieces – all configurable to your requirements.

What other packaging solutions does Conwed offer for manufacturers?

In addition to protective sleeves, Conwed provides a broad portfolio of netting-based packaging solutions to address various material handling and packaging needs:

- Case and Grip Liners: These are flexible netting liners used in shipping cases, boxes, or on shelves. They cushion and hold items in place, providing exceptional protection for valuable objects and also adding an attractive non-slip display surface (often used for produce, meats, or fragile goods in display cases). Grip liners come in different styles (e.g., standard vs. air-cushioned) to prevent slippage and protect delicate items on inclined or vibrating surfaces.

- Consumer Product Packaging Nets: Conwed produces extruded netting to contain and package consumer goods. For example, our nets are used to bag or wrap items like marbles, toys, candies, and other small products, keeping them secure while allowing visibility and airflow. This helps manufacturers and retailers pack diverse products (from artificial decor to candy) in a way that is lightweight, breathable, and visually appealing.

- Food Processing & Meat Nets: We supply specialized netting for the food and beverage industry – including food processing mesh and meat/poultry netting. These nets can be used in packaging, curing, or even cooking applications (such as netting that holds hams or roasts). They are made with food-grade resins and come in configurations (different thicknesses, hole sizes) suited to withstand processes like marinating or cooking, offering excellent tensile strength and durability for these demanding uses.

- Pallet Netting: Conwed’s pallet netting solutions help manufacturers and distributors secure palletized loads. Rather than using stretch film alone, a flexible net is draped or wrapped around a loaded pallet to contain and stabilize even odd-shaped or unstable loads. This ensures that goods on pallets stay in place during transit while enabling ventilation (important for certain products). Pallet netting is reusable and can improve handling efficiency for warehouse and transport operations.

- Produce Bags (Flexible Mesh Bags): For agricultural and produce packaging, we offer soft, diamond-mesh produce bags that gently conform around fruits and vegetables. These bags provide enough support and protection to prevent bruising while allowing air to circulate, which keeps produce fresh. They also enhance retail presentation by showcasing the contents.

Closing the loop for a circular economy – PCR netting for packaging

Did you know we offer a netting made from up to 30% post-consumer- recycled plastics? Close the loop with Conwed’s post-consumer-recycled plastic netting. Get the same strength and reliability you trust, while reducing your product carbon footprint and meeting EPR...

Protective Netting Sleeves for Packaging, Handling, and Processing

Protective netting sleeves have become essential in packaging, handling, and processing environments where product integrity and operational efficiency matter most. When valuable components make their way through complex supply chains or are maneuvered in busy...

Everything You Need to Know About Tubular Netting for Onion Packaging

Packaging plays a critical role in the success of fresh produce businesses, ensuring that products remain protected, attractive, and easy to transport. Among the various solutions available, tubular netting has emerged as one of the most effective options for produce...

Q&A with Ron Delcastillo, Regional Sales Manager and Packaging Expert at Conwed

We recently had the pleasure of interviewing Ron Delcastillo, Regional Sales Manager at Conwed. Ron has been instrumental in driving innovation and enhancing customer experience at Conwed. He’s passionate about Conwed packaging, and having been with the company since...