Carpet cushion manufacturers face several operational hurdles that directly impact their bottom line. High-speed production lines often experience material tears and inconsistencies that force costly slowdowns. Without proper reinforcement, recycled urethane foam can become unstable during processing, leading to increased waste and reduced throughput.

Beyond manufacturing concerns, carpet cushions must perform reliably throughout their installation and service life. Installers frequently struggle with materials that stretch, tear, or buckle during installation. Poor dimensional stability makes cutting and positioning difficult, extending installation time and increasing labor costs.

The end-user experience depends heavily on the cushion’s ability to distribute weight evenly and resist wear over time. Without proper reinforcement, cushions may develop weak spots, leading to premature failure and customer dissatisfaction. These issues create warranty claims and damage brand reputation.

Carpet cushion reinforcement technology offers a solution to enhance manufacturing processes and deliver superior products.

Benefits of Reinforced Carpet Cushions

Manufacturing Advantages

Reinforced cushions improve bonding strength, reduce waste, and allow faster production speeds. Consistent quality reduces testing needs, increasing efficiency and profitability

Installation Benefits

The reinforcements simplify installation with improved stability, tear resistance, and ease of positioning. Installers benefit from faster, more reliable workflows, reducing callbacks and errors.

Customer Advantages

Structural nettings allow it to last longer, distribute weight evenly, and resist wear, reducing replacement costs and enhancing customer satisfaction.

Conwed’s Reinforcement Netting

Advanced Bi-Axial Orientation Technology

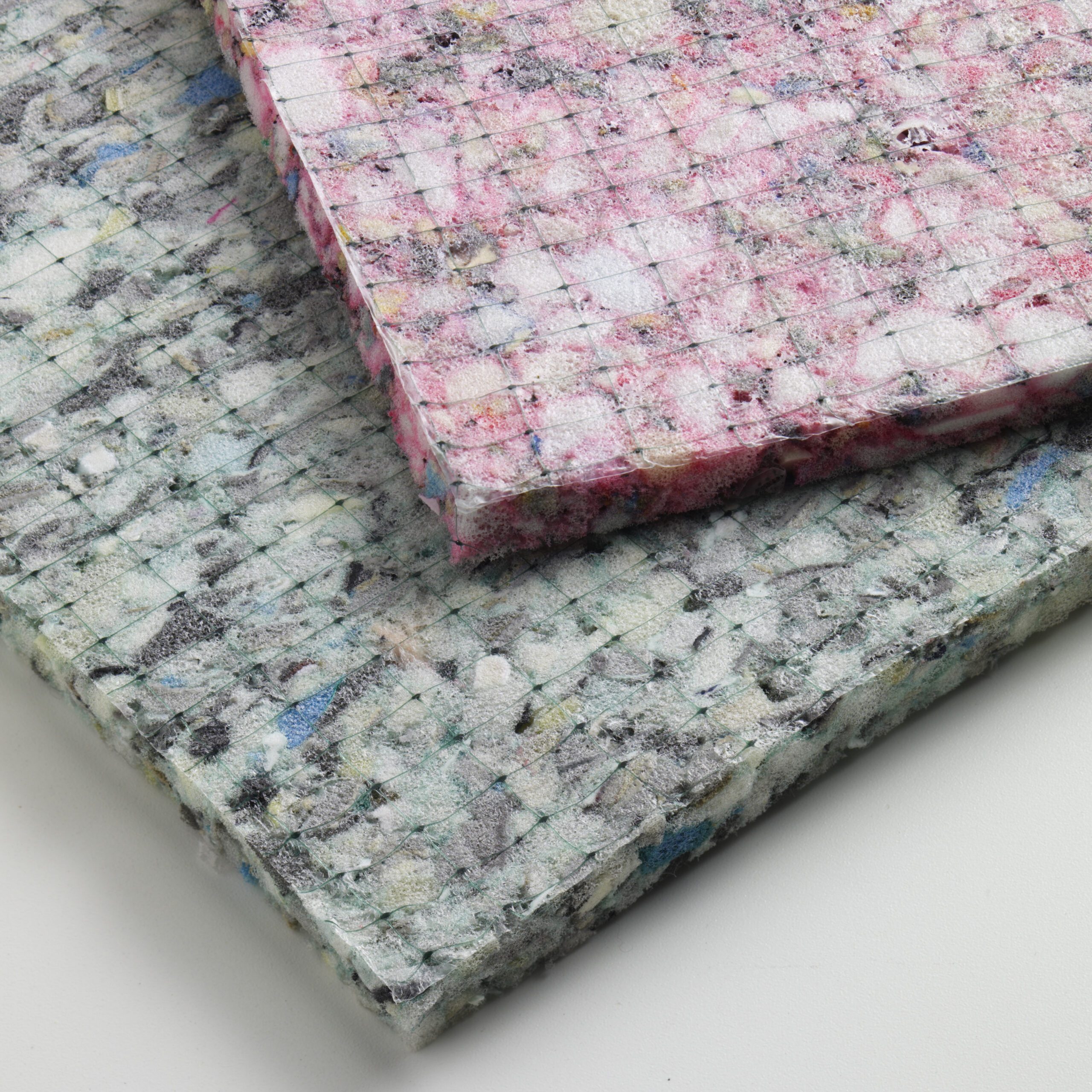

Conwed™ Netting represents a breakthrough in carpet cushion reinforcement technology. The unique bi-axial orientation process creates a lightweight configuration with exceptional dimensional stability and superior tensile strength in both strand directions. This manufacturing approach ensures consistent performance across the entire surface area.

The netting integrates seamlessly with recycled urethane foam through lamination processes. This combination creates a composite material that maintains the cushioning properties of foam while adding structural integrity that prevents common failure modes. The result is a reinforced cushion that performs better and lasts longer than traditional alternatives.

Material Properties and Durability

The engineered properties of Conwed™ netting address the challenges faced by carpet cushions. The material is non-corrosive, and mildew-resistant, ensuring long-term performance in various conditions. It remains unaffected by water, most acids, gases, chemicals, and organic materials.

Netting Customization at Conwed

The decision to implement reinforcement technology should be based on a thorough understanding of your specific manufacturing requirements. The flexibility of netting solutions allows customization to meet unique application needs while maintaining the core benefits of reinforcement. At Conwed we specialize in manufacturing netting solutions to fit unique customer requirements for even the most demanding applications.

Ready to transform your carpet cushion manufacturing operations? Contact our technical team to discuss how Conwed™ Netting solutions can address your specific challenges and opportunities. Our experts will work with you to develop a customized netting solution that maximizes the benefits of reinforcement technology for your business.

For more information about our reinforcement netting for carpet cushions, click here.