Flow Media for Resin Infusion

Engineered to outperform traditional flow media in vacuum-assisted resin transfer molding (VARTM) and resin infusion processes.

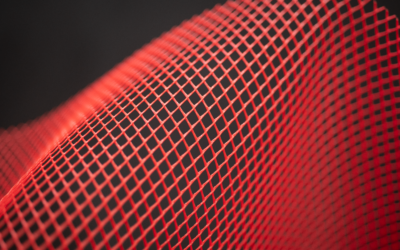

Conwed™ Flow Media, made from Naltex™ Extruded Netting, is engineered to outperform traditional flow media in vacuum-assisted resin transfer molding (VARTM) and resin infusion processes. Designed for high-performance applications in aerospace, marine, and automotive industries, it delivers faster resin flow, reduced waste, and consistent quality – making it the smarter choice for manufacturers seeking to optimize composite production.

Benefits of Conwed Flow Media:

- Up to 15% Less Resin Waste – Our optimized diamond mesh geometry retains significantly less resin than leading flow media, reducing material costs and part weight.

- Accelerated Resin Flow – Bi-planar netting ensures fast, uniform resin distribution across complex geometries, shortening fill and cure times.

- No Fray, No Fiber Contamination – Unlike woven meshes, our extruded netting won’t unravel or shed fibers, ensuring clean lay-up and protecting vacuum bags and peel plies.

- High Thermal and Chemical Resistance – Available in polypropylene, polyamide, and PBT to match your resin system and temperature requirements – up to 150°C.

- Global Manufacturing & Support – Produced in ISO 9001-certified facilities in North America and Europe, with fast lead times and technical support.

- Additional Media and Services – Argotec manufactures TPU film for vacuum bags and wind turbine blade leading edge protection for tape manufacturers. In-house lamination and slitting are also available

Why Conwed Flow Media for Resin Infusion?

- Allows the use of higher-viscosity resin

- Reduces fill time

- Shortens mold cycle time

- Extruded – NOT woven

- Will not unravel or fray

- Flow channels enhance liquid and airflow

Why Choose Conwed’s Naltex™ Flow Media?

- Proven resin savings vs. traditional flow meshes

- Cleaner handling with no fraying or fiber shedding

- Customizable formats and materials for your process

- Global supply chain reliability and technical expertise

Conwed™ Announces Exclusive Savings Up to 50% with The New Tariffs – Limited Availability

Minneapolis, MN, USA – April 2025 – Conwed, a leader in locally manufactured industrial netting solutions, has announced a limited-time offer providing businesses with savings of up to 50%* on 2025 tariffs for sourcing their products. This initiative is designed to...

Naltex™ Flow Media – Fully Optimized Resin Infusion in VARTM for Wind Turbine Manufacturing

Harnessing Resin Infusion for Wind Turbine Manufacturing With global efforts centered on transitioning to renewable energy, the demand for innovative and efficient fabrication methods in the wind energy sector has never been greater. By combining cost-efficiency with...

Meet Our Team at JEC World 2025 – Leading Innovation in Composites

From March 4–6, 2025, the world of composites will converge in Paris for JEC World—the premier international composites show. At Conwed, we’re excited to showcase our cutting-edge materials and solutions that are shaping industries like wind energy, marine, sports,...

Conwed™ Presents Advanced Naltex™ Nettings for Composite Fabrication Applications at JEC in Paris

Minneapolis, MN, USA – January 2025 – Conwed, a Mativ Brand, is a global leader in industrial netting solutions and proud to present the Naltex™ Resin Distribution Netting, an innovative flow media designed to optimize composite fabrication processes such as VARTM...