Protective netting sleeves have become essential in packaging, handling, and processing environments where product integrity and operational efficiency matter most. When valuable components make their way through complex supply chains or are maneuvered in busy facilities, the right packaging protection can make the difference between flawless delivery and costly damage.

Why Netting Sleeves Matter in Packaging, Handling, and Processing

From high-volume warehouses to specialized fabrication lines, packaging and handling experts face a shared challenge. How do you consistently protect goods with unusual shapes, delicate finishes, or demanding storage requirements? Traditional packaging is often rigid, single-use, or simply not versatile enough.

Netting sleeves solve these issues across countless applications:

Flexible Coverage

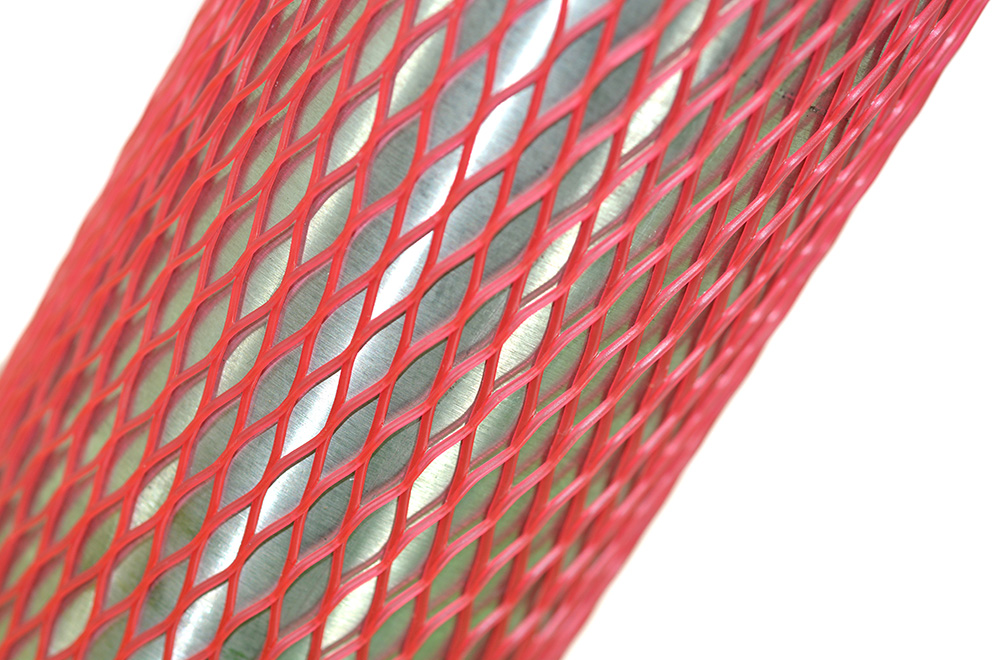

Whether you’re dealing with glassware, metal rods, high-pressure cylinders, or unique industrial parts, netting sleeves stretch and conform to nearly any contour. This creates a protective layer that prevents scratches, dents, and surface damage during transit and handling.

Ventilation and Drainage

Unlike solid covers, netting sleeves allow air to circulate and moisture to escape. This reduces condensation, corrosion, and the buildup of residues, especially important in food processing and sensitive material handling.

Cost and Time Efficiency

Lightweight yet tough, these synthetic sleeves are quick to apply and remove. They reduce the need for bubble wrap, foams, or custom-fitted packaging, helping organizations save on both material and labor costs.

Reusability

Most protective mesh sleeves are reusable throughout an item’s manufacturing and distribution cycle, contributing to less packaging waste compared to traditional disposable methods.

Versatility Across Industries

Netting sleeves are used as parts separators, cylinder covers, bottle protectors, pipe guards, and more. Whether you manage bulk packaging or individual sensitive products, netting can be adapted for the job.

Our Netting Solutions

At Conwed, we deliver a complete line of protective netting sleeves under our trusted Naltex™ and Vexar™ brands. Our sleeves are engineered for reliable protection in the most demanding settings.

Naltex and Vexar Protective Mesh Sleeves:

- Unmatched Flexibility and Strength

Both Naltex™ and Vexar™ sleeves combine robustness with excellent flexibility. This allows our sleeves to wrap virtually any object, from delicate glassware to heavy machinery components, ensuring optimal cushioning and secure immobilization during movement.

- Comprehensive Product Range

We offer protective sleeves in a wide array of resins, colors, thicknesses, and mesh sizes. This means custom-fit solutions for every product and application, whether you require enhanced visual identification with color coding or tailored mechanical performance.

- Bulk and Custom Sizing

Our sleeves are available pre-cut to client specifications or in large bulk rolls for on-site customization, enabling seamless integration into packaging lines and handling processes of all sizes.

- Chemical and Environmental Resistance

Constructed from high-quality synthetic materials, our sleeves stand up to moisture, oils, and many chemicals, making them ideal for industries that demand durability and longevity.

Beyond the Basics

Netting sleeves from Conwed aren’t just for packaging and transportation. They provide reliable part separation and damage prevention during finishing, coating, and painting processes, ensuring that final products reach customers in pristine condition.

Our protective sleeves are used for everything from separating assembly line parts to safeguarding furniture, packaging bottles, and storing bulk materials. Trusted across diverse sectors including packaging, agriculture, consumer goods, industrial manufacturing, and transportation, our netting sleeves offer versatile solutions for many industries.

What Sets Conwed Apart

Choosing the right protective netting partner is essential. At Conwed, our value comes from a unique blend of engineering expertise, industry experience, and relentless commitment to customer satisfaction and highest quality standards.

Engineering Excellence

Decades of research and innovation have allowed us to develop netting sleeves that balance flexibility, toughness, and product safety. We work closely with clients to tweak material formulations, mesh configurations, and product dimensions so every sleeve delivers maximum performance.

Customization and Speed

No two projects are the same. We offer rapid prototyping, broad customization options, and streamlined ordering processes to ensure you get netting sleeves perfectly suited for your operation.

Consistent Quality Control

From raw material selection to finished product inspections, every step of our manufacturing follows strict quality protocols. This attention to detail ensures reliability in every shipment and confidence for every customer.

Comprehensive Support

Our team believes in long-term partnerships. We don’t just supply netting – we provide technical guidance, recommend best-fit solutions, and are available to troubleshoot packaging and processing challenges as they arise.

Move Forward With Superior Product Protection

Effective packaging and handling solutions shouldn’t be an afterthought. Protective netting sleeves offer an efficient, versatile, and eco-conscious way to ensure product safety from the first mile to the last.

Whether you’re safeguarding fragile bottles, rugged parts, or anything in between, Conwed delivers proven netting solutions tailored to your operation. Our industry expertise, commitment to customization, and wide-ranging product line make us the trusted partner for packaging, handling, and processing professionals worldwide.