Conwed™ Netting Configurations

Every product application requires precise netting designs to achieve target performance.

Conwed has a portfolio of netting configurations from which modifications can be made until the most suitable product is identified. In addition to square, flat, and diamond netting, Conwed also manufactures specialty products such as extruded cylinder tubes, co-extrusion, bi-component, and multilayer netting, allowing us to offer a versatile netting portfolio.

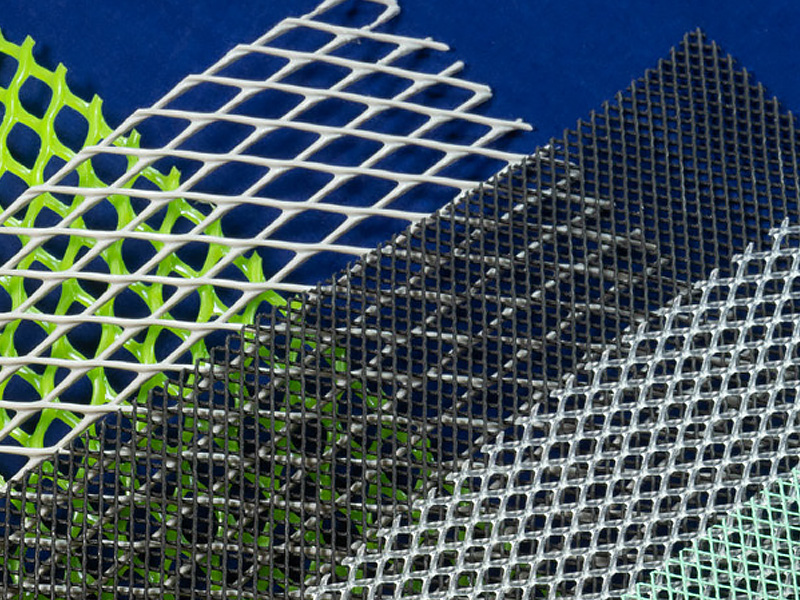

Conwed Netting Types

Conwed™ Square Netting

Square netting is a standard configuration in our extrusion process. Mesh angles are 90°, and strands run transversely in Machine and Cross Directions. Square netting can be subsequently oriented to create lighter-weight yet strong configurations

Conwed™ Diamond Netting

This is an extruded netting with a diamond shape configuration. One major difference between square and diamond netting is that diamond netting is bi-planer.. The strands appear to run diagonally in both Machine and Cross Directions to form the diamond mesh design.

Conwed™ Flat Netting

Flat netting is a square netting configuration with flat joints and uniform thickness. A flat surface can be designed during the extrusion process, or it can also be achieved by calendering an extruded square netting. Each process delivers different flat netting configurations and performance functionalities.

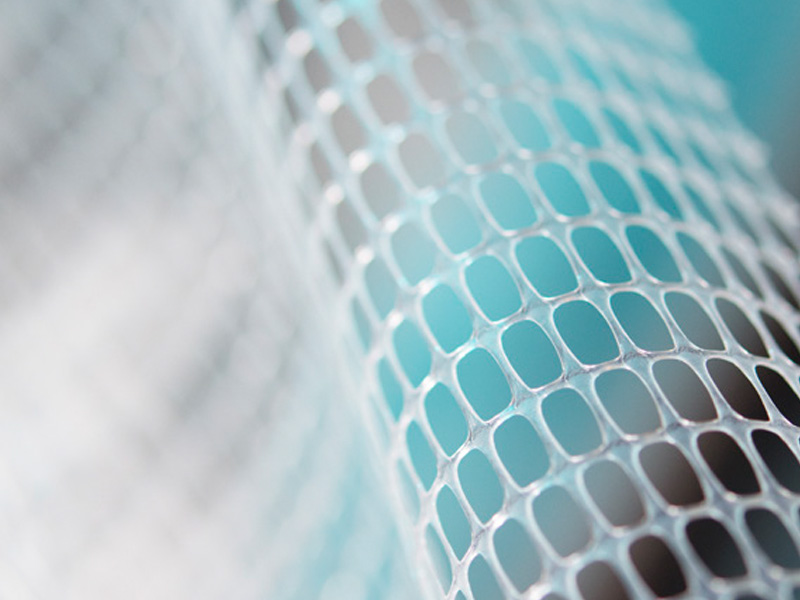

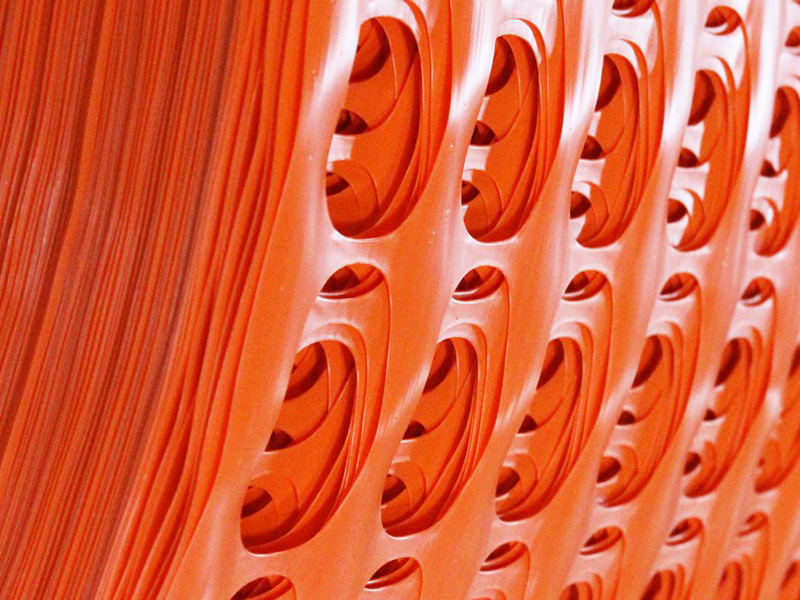

Conwed™ Extruded Cylinder Tube

It is an extruded plastic tube in cylinder form made in a continuous extrusion process that yields a material with integral joints. All of our extruded cylinder tubes have a square mesh configuration. Unlike seamed netting tubes, extruded cylinder tubes are stronger because of their consistent cylindrical shape made in one single step.

Conwed™ Co-Extrusion Netting

Co-extrusion is a multi-layer extruded netting that can subsequently be oriented where different polymers can form different layers on the same configuration. It is a square netting construction, and Conwed can build netting with A/B, A/B/A, and A/B/C layer combinations.

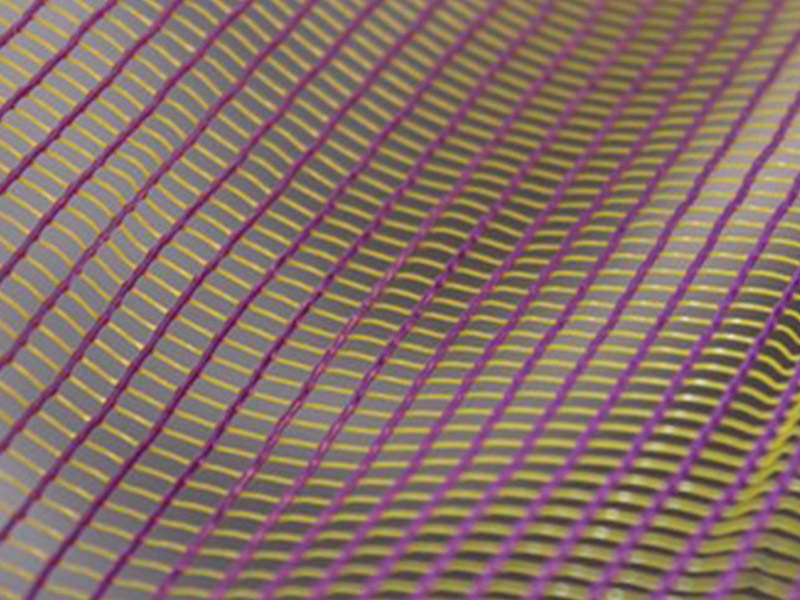

Conwed™ Bi-Component Netting

Bi-component netting is made of two materials, one in each opposite direction, forming the web. Conwed can combine different, compatible resins in the same netting configuration but in opposite directions.

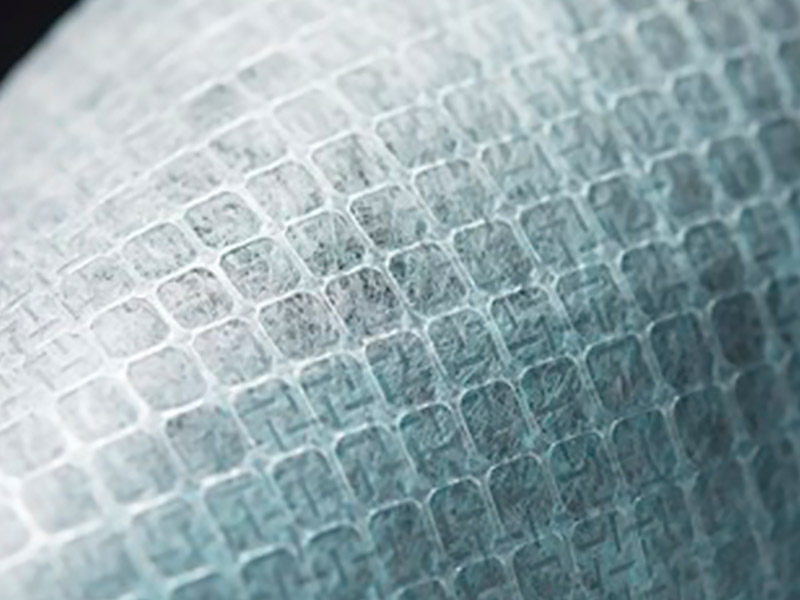

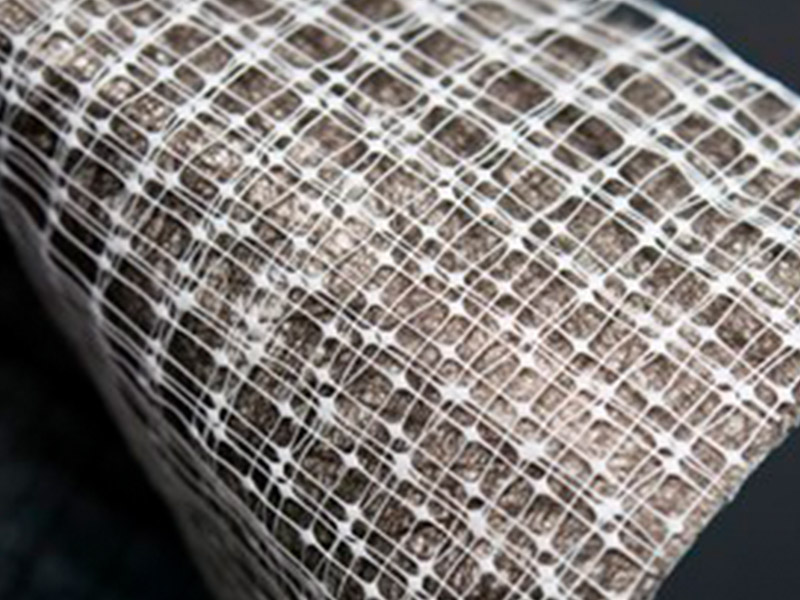

Conwed™ Multilayer Netting

Multilayer netting is a configuration formed by multiple layers of oriented netting laying one on top of another, creating a strong but lightweight mesh compatible with different substrates. It is an ideal alternative to other reinforcement materials such as cross-laminated fabrics, cross-laid scrims, and knitted scrims.

Advanced Netting Solutions in Food Processing

Innovations in the food processing industry are continuously shaping how food is produced, packaged, and delivered to customers around the world. With increasing consumer demand for efficiency, sustainability, and quality, businesses within this sector face the...

Everything You Need to Know About Tubular Netting for Onion Packaging

Packaging plays a critical role in the success of fresh produce businesses, ensuring that products remain protected, attractive, and easy to transport. Among the various solutions available, tubular netting has emerged as one of the most effective options for produce...

Efficient and Reliable Hay Bale Netting

With the agricultural season ramping up in spring, the agricultural season begins to pick up pace. For farmers and ranchers, this often means long hours harvesting hay and forage. Ensuring this feed is stored appropriately and protected from harsh weather conditions...

Durable Protection for Paving Stones in Storage and Transit

Every construction professional and homeowner knows that the beauty and functionality of high-quality paving, concrete, and architectural blocks come at a cost. A well-crafted paving design is a reflection of precision, durability, and aesthetic appeal. But the effort...

Conwed™ Bird & Animal Protection Netting

Protecting your crops and animals has never been more critical. With rising awareness of bird flu and its potential threats to agriculture and animal farming, ensuring safety measures is a priority for farmers, vineyard owners, and poultry farmers. One of the most...

Conwed™ Wattle Netting & Socks for Wildfire Erosion Control

Wildfires leave a devastating mark on our landscapes. The recent fires in California are yet another reminder of how these disasters can strip entire regions of their vegetation, destabilizing ecosystems and putting communities at risk of long-term damage. After the...