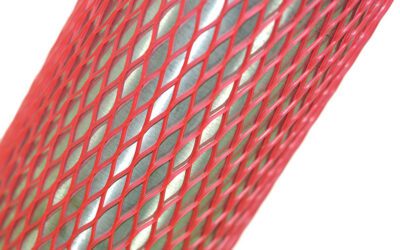

Naconet™ – Compostable Netting

The Future is Plastic-Free.

Protect the Environment. Preserve Wildlife. Comply with Tomorrow’s Standards – Today.

Bring innovation and responsibility to your market with Conwed’s all-new bio-based Naconet™ netting solutions. Conwed’s Naconet™ is a next-generation, bio-based netting solution designed to meet the needs of modern industries seeking high performance without environmental compromise. Whether you’re in agriculture, aquaculture, food packaging, erosion control, or green infrastructure, Naconet™ delivers the strength and reliability you expect – with the sustainability the planet demands.

High Performance Meets Sustainability

At Conwed, we understand that you shouldn’t have to choose between high performance and sustainability. Our bio-based net delivers unmatched reliability and eco-friendliness, allowing you to maximize efficiency while meeting your environmental goals – means, you’re not loosing any performance with our latest development.

Naconet™ vs. Conventional Plastic Netting:

A Smarter, Sustainable Alternative

Looking for a high-performance netting solution that doesn’t compromise the planet? Meet Naconet™ – a compostable, extruded netting that delivers the same strength and reliability as traditional plastic netting, without the environmental cost.

-

Compostable and Plastic-Free

Unlike conventional plastic netting that can persist in the environment for decades and break down into harmful microplastics, Naconet™ is made from bio-based materials that fully compost into natural elements like water, CO₂, and biomass. No toxic residues. No long-term pollution. -

Engineered for Performance

Naconet™ is designed to match the tensile strength, UV resistance, and flexibility of plastic netting. Whether used in agriculture, packaging, erosion control, or aquaculture, it performs reliably throughout its intended lifespan. -

Regulatory Ready

As global regulations tighten around single-use plastics, Naconet™ helps your business stay compliant. It meets compostability standards, making it an ideal choice for companies committed to sustainability and future-proof operations. -

Consistent and Equipment-Friendly

Compared to natural fiber alternatives like jute or coir, Naconet™ offers greater consistency, smoother handling, and compatibility with modern machinery. It’s also a truly compostable solution that only fragment into microplastics

Naconet™ delivers all the benefits of conventional plastic netting – support, containment, and protection – without the environmental downsides. It’s the smart, sustainable choice for industries ready to align performance with purpose.

Why Choose Naconet?

-

- Made from sustainable materials

- Industrial Compostable

- Breaks down into CO₂, water, and biomass – no microplastics

- Non-toxic and safe for soil, water, plants, animals, and food contact

- No post-use removal or landfill disposal required

- Compatible with standard netting and packaging equipment

- Manufactured in the USA and Europe for global availability and reduced emissions

Benefits of Conwed's Naconet™ - our compostable netting

100% Industrial Compostable

Made from certified compostable materials that break down into CO₂, water, and biomass – leaving no plastic waste or microplastics behind.

Regulatory Compliance & Future-Readiness

Meets global compostability standards and helps businesses stay ahead of tightening plastic regulations.

Strong, Reliable Performance

Engineered for durability and reinforcement across diverse applications – from agriculture and aquaculture to packaging and erosion control.

No Post-Use Cleanup

Naconet™ decomposes naturally in place, eliminating the need for costly removal, landfill disposal, or long-term maintenance

Safe for the Environment & Wildlife

Non-toxic and free from harmful chemicals, with a loose-weave design that minimizes risk to wildlife and aquatic species.

Global Manufacturing in the USA & Europe

Produced in both North America and Europe to ensure consistent quality, regional availability, and reduced transportation emissions – supporting your sustainability goals worldwide.

Join the Green Revolution in Your Industry – with Naconet™

Switching to Conwed’s bio-based, compostable Naconet™ netting solutions in different industries is a smart move towards sustainability.

Sod & Turf: Sustainable Production & Installation

Naconet™ offers a clean, high-performance alternative to traditional plastic sod netting. It provides the necessary structural support during turf production and installation, then safely biodegrades in the soil—eliminating long-term plastic residue, wildlife hazards, and costly removal. For turf growers and landscapers seeking sustainable, low-maintenance solutions, Naconet™ is the future of responsible turf reinforcement.

Erosion Control: Compostable Nets for Soil Stabilization

In erosion control, Naconet™ delivers reliable soil stabilization with none of the long-term environmental damage caused by plastic netting. Its compostable, extruded design meets wildlife-safe standards and decomposes fully after use, supporting vegetation growth and eliminating the need for retrieval. For land restoration, infrastructure, and conservation projects, Naconet™ is the sustainable standard.

Packaging: Compostable Produce & Product Netting

Naconet™ is a certified compostable netting solution for produce and product packaging. Made from bio-based materials, it offers the strength, breathability, and food safety of plastic – without the waste. Unlike traditional plastic mesh, Naconet™ helps brands meet global packaging regulations and sustainability goals. It runs on standard packing equipment, keeps produce fresher longer, and appeals to eco-conscious consumers. Ideal for plastic-free packaging, Naconet™ supports zero-waste initiatives while maintaining performance and shelf appeal.

Crop & Animal Protection: Safe Nets for Agriculture and Livestock

Naconet™ is a compostable netting solution for agriculture and livestock protection. Designed to replace plastic crop nets, deer fencing, and hay bale wrap, it offers strong performance while fully compostable after use. Unlike plastic, Naconet™ won’t leave microplastics in soil or pose risks to wildlife. It’s compatible with standard farm equipment, supports organic certification, and simplifies waste management. Ideal for sustainable farming, Naconet™ helps reduce plastic pollution while protecting crops, animals, and the environment.

Green Roofing: Eco-Friendly Erosion Control on Roofs

Naconet™ is a compostable netting solution for green roofs, offering effective erosion control without the long-term pollution of plastic mesh. Designed for sloped or vegetated roofs, it stabilizes soil during plant establishment and naturally biodegrades, eliminating microplastic runoff and drainage issues. Naconet™ supports LEED and green building certifications. and simplifies maintenance. Ideal for sustainable roof design, it replaces synthetic netting with a high-performance, eco-friendly alternative that disappears when no longer needed.

Everything You Need to Know About Naconet™,

Conwed’s Compostable Netting Solution

What is Naconet™ compostable netting?

Naconet™ is a fully compostable, bio-based netting designed as an eco-friendly alternative to traditional plastic netting. Developed by Conwed’s R&D team, Naconet™ is engineered to deliver the same performance as conventional plastic nets – providing strong mesh support for products like sod, turf, and more – without leaving behind persistent plastic waste. In other words, it does the job of stabilizing or packaging products just as effectively as polypropylene nets, but once its job is done it biodegrades safely instead of remaining in the environment.

This innovation was driven by industry demand for sustainable solutions: growers, landscapers, and manufacturers wanted a netting that performs like plastic but doesn’t create long-term pollution. With Naconet™, businesses can maintain their usual operations (same equipment and usage) while making a significant positive impact on the environment. It’s part of Conwed’s new development of sustainable nettings, aiming to help users reduce their carbon footprint and meet rising sustainability goals without sacrificing quality or efficiency.

What is Naconet™ made from (what’s the raw material)?

Naconet™ is made from renewable plant-based polymers – specifically a biopolymer derived from natural plant sugars. The netting’s primary raw material is often polylactic acid (PLA), a polymer created by fermenting plant sugars (from sources like corn or sugar beets) into lactic acid, then polymerizing it into a durable fiber. In simpler terms, instead of petroleum-based plastic,

Naconet™ uses 100% bio-based ingredients from plants. These plant-derived polymers are certified compostable and break down into natural components (carbon dioxide, water, and organic biomass) when composted. Because the material comes from atmospheric carbon (captured by plants through photosynthesis) and returns to natural elements at end-of-life, it contributes far less to long-term pollution.

The PLA in Naconet™ is the same type of safe bioplastic used in compostable cups and even medical sutures, so it’s proven to be non-toxic and environmentally benign. In summary, Naconet™’s netting is made from plants, not oil – offering a sustainable composition that’s strong in use but gentle on the planet.

Is Naconet™ really compostable and does it fully biodegrade?

Yes – Naconet™ is truly compostable and fully biodegrades under the proper conditions. It has been certified industrially compostable by the Biodegradable Products Institute (BPI), which means it meets the ASTM D6400 standard for compostability. In an industrial composting environment (high heat ~60°C, moisture, microbes),

Naconet™ netting will disintegrate and biodegrade completely within about 180 days. During this process, the material breaks down into natural end products – primarily carbon dioxide, water, and biomass (humus) – leaving no persistent microplastics or harmful residue behind. This has been validated by third-party testing: as part of its certification, the netting passed strict tests to ensure it leaves no toxic heavy metals and does not inhibit plant growth in the resulting compost.

It’s important to note that “compostable” means it transforms into natural compost under composting conditions. In practical terms, after you use Naconet™, you do not need to pull it out – you can let nature do the work. In soil or ambient conditions, the breakdown will take longer than 180 days (since those are optimal lab compost conditions), but the key is that it will eventually biodegrade completely, given moisture and microbial activity. Unlike conventional plastic, which can linger for decades, Naconet™ won’t leave long-term fragments. In fact, scientific studies on PLA (Naconet™’s base material) show that once it starts breaking down, it fully hydrolyzes and biodegrades rather than stopping at microplastic-sized pieces. In short, Naconet™ is designed to go “back to nature” at end-of-life, fulfilling the promise of a compostable product.

How does Naconet™ compare to traditional plastic netting?

Naconet™ was designed to match or exceed the performance of traditional plastic netting while eliminating the environmental downsides of plastics.

Here’s a side-by-side comparison across key factors:

| Aspect | Naconet™ Compostable Netting | Traditional Plastic Netting |

| Material Source | Made from 100% bio-based polymers (renewable plant sugars, e.g. PLA). No petroleum content. | Made from petrochemical polymers (e.g. polypropylene) derived from fossil fuels |

| Biodegradability | Fully compostable – breaks down into CO₂, water, and biomass with no microplastics left behind. | Non-biodegradable – will not decompose naturally. Remains intact for decades; eventually fragments into persistent microplastics if left in the environment. |

| Environmental Impact | Low environmental impact: Made from renewable resources (lower net CO₂ emissions) Safe for soil and wildlife – no toxic residues; eliminates plastic pollution and wildlife entanglement risk | High environmental impact: Production and disposal contribute to carbon emissions. If left in fields, plastic nets can snare wildlife (birds, snakes) and pollute soil/water as they break into microplastics |

| In-Use Performance | High-performance mesh: Engineered to match the strength, flexibility, and durability of plastic nets. Supports heavy loads (e.g. sod rolls, bales) through use; maintains integrity as long as needed, then degrades only after its job is done. | Proven strength: Industry-standard tensile strength and durability for securing products. However, remaining plastic mesh can interfere with plant regrowth or equipment if not removed (e.g. mower tangles, root restriction). |

| After Use / Disposal | No removal required: Naconet™ can be left in place to biodegrade naturally – saving labor and avoiding waste hauling. In industrial compost, it disappears in ~6 months. No landfill needed. | Requires removal: Must be physically removed and landfilled or otherwise disposed, since it won’t degrade on its own. If not removed, old plastic nets persist indefinitely, causing long-term cleanup costs and potential regulatory fines. |

| Cost & Lifecycle | Upfront cost may be slightly higher than commodity plastic netting (due to advanced materials). Lifecycle cost is often lower: saves on retrieval/cleanup labor, disposal fees, and avoids hidden costs (equipment damage, liability from leftover plastics. Also boosts sustainability credentials, which can win contracts and customer loyalty. | Upfront cost is usually lower per roll (standard plastic is cheap). Downstream costs can accumulate: paying workers to gather and dispose of old nets, repairing machinery or landscaping affected by stray plastic, and potential compliance costs as environmental regulations tighten. |

As shown above, Naconet™ delivers the same essential functions (strength, support, ease of use) that users expect from plastic netting. The big differences come after its use: instead of a legacy of pollution, Naconet™ simply disappears, making it a far superior choice for those looking to reduce long-term environmental impact. While initial material costs for compostable biopolymer are a bit higher, many users find that the savings in labor and the goodwill gained by using a green solution easily offset the cost. In short, you get all the benefits of traditional netting – with none of the guilt or cleanup headaches.

Do I need to remove Naconet™ netting after use, or how do I dispose of it?

One of the major advantages of Naconet™ is that you do not need to remove it after it has served its purpose. Unlike plastic netting which must be painstakingly pulled out of soil or off products and then sent to a landfill, Naconet™ can be left in place to naturally biodegrade. For example, if Naconet™ is used to hold a sod roll or an erosion control blanket, you can install it and leave it in the ground; over the following months it will break down into the soil on its own. There’s no netting to collect, no disposal or burning required – it essentially disposes itself by composting in situ. This “leave it and forget it” disposal means lower maintenance and labor costs: crews don’t have to return to job sites to clean up mesh, and landowners won’t be digging out old plastic mesh years later.

If you do remove Naconet™ (say, it’s used in a product packaging that gets unwrapped), the proper way to dispose of it is to send it to a commercial composting facility if available, or at least to a yard waste collection. Industrial composting will ensure it breaks down quickly (within ~6 months). Even if it ends up in soil or mixed into compost at home, it will still biodegrade over time – the key is that it will not persist like plastic. By using Naconet™, you essentially eliminate a whole step in the lifecycle: disposal is as simple as letting nature take its course, freeing you to focus on your work rather than cleanup. This not only saves effort but also prevents adding any waste to landfills. As one marketer summed it up: “With Naconet™, what you install is what you leave – there’s no need to come back and pick up decaying plastic mesh”. That means no lingering debris, no long-term liability, and no hassle.

Is Naconet™ certified or compliant with sustainability standards (compostability, etc.)?

Yes. Naconet™ has undergone thorough third-party certification to validate its compostability and safety. It is certified by BPI (Biodegradable Products Institute), indicating it meets the ASTM D6400 standard for compostable plastics. This standard requires that the material disintegrates and biodegrades fully in industrial composting conditions within a defined timeframe and leaves no eco-toxic residue.

Additionally, the raw materials and final netting have been tested for safety and environmental compliance. Compostability certification includes ecotoxicity tests and heavy metal tests to ensure that when Naconet™ breaks down, it doesn’t harm soil organisms or plants. Naconet™ passed these tests, confirming that it is non-toxic and safe in the environment. The product contains no hazardous substances and is free of BPA, phthalates, or other concerning chemicals commonly associated with plastics. It also adheres to any relevant food-contact or agricultural use regulations if applicable (for instance, PLA is generally recognized as safe and has been used in food packaging and medical implants).

In summary, you can trust that Naconet™’s green credentials are the real deal – it carries the certified compostable labels and meets all necessary sustainability standards, giving you and your customers peace of mind. Using Naconet™ can also help meet government or industry sustainability requirements (for example, projects pursuing green procurement or meeting new plastic reduction laws), since it is an approved compostable material rather than a single-use plastic.

What are the main applications or industries where Naconet™ can be used?

Naconet™ is a versatile netting solution that can replace plastic mesh in a wide range of industries and uses. It was initially developed with agriculture and landscaping in mind, but its applications are broad wherever netting is needed. Key use cases include:

- Turf & Sod Farming: Naconet™ can be used as sod netting to hold together rolls of turf grass. Traditionally, plastic netting is embedded in sod to stabilize it during harvesting and installation; with Naconet™, growers get the same support but the netting biodegrades into the lawn after the grass takes root. This is ideal for golf courses, sports fields, and lawns, eliminating the headache of plastic mesh left in the soil.

- Erosion Control & Land Restoration: In erosion control blankets/mats (used on slopes or construction sites to prevent soil washout and help vegetation grow), Naconet™ serves as the mesh that reinforces the blanket. It provides reliable erosion control during the critical period, then composts into the soil once grasses and plants establish. This ensures “clean soil integration” – no plastic bits left behind – and improved soil health over time. It’s a high-performance, sustainable solution for highway embankments, landscaping projects, and land management where current plastic or jute nets are used.

- Agriculture & Horticulture: Farmers and growers can use Naconet™ in place of plastic for various needs. Naconet™ is suitable for crop protection nets and trellis netting (supporting climbing plants, protecting orchards from birds, etc.) – it offers the same support and barrier, but if a piece is lost in the field, it won’t harm the environment. Vineyard netting or nursery plant nets are other potential uses, helping agriculture cut down on plastic waste.

- Produce & Product Packaging: Packaging netting (those mesh bags for fruits, vegetables, shellfish, or even toy balls) is another area. Naconet™’s technology can be made into flexible net packaging for items like onions, citrus fruits, potatoes, or seafood, providing breathability and protection just like current poly nets. The big benefit is that the entire net bag is compostable – consumers or retailers can toss it in compost instead of trash. This appeals to supermarkets and brands looking to eliminate single-use plastics in packaging. It keeps produce fresh and secure during transport, then breaks down after disposal, aligning with sustainable packaging goals.

- Horticulture & Retail Garden Products: Naconet™ can be used in garden center products – for instance, around root balls of trees or shrubs (similar to burlap or plastic wrap used now) so that when planted, the netting composts. It’s also suitable for garden netting and twine (like tying plants, netting for climbing vines, etc.) where gardeners want an eco-friendly option. Even temporary fencing or netted enclosures (for poultry or game in a field) could use a compostable net that eventually breaks down if not removed.

- Wildlife and Bird Netting: For protecting ponds, fruit trees, or structures from birds without harming them, Naconet™ provides a safe alternative. Traditional plastic bird nets can entangle wildlife; a compostable net still deters birds but if left outdoors accidentally or pieces fall off, they will degrade and not pose a long-term threat. This is especially useful in environmentally sensitive areas.

In essence, any place you currently use extruded plastic netting, you could consider using Naconet™ instead. It’s designed for “drop-in” replacement in terms of dimensions and performance (available in standard roll sizes and configurations to fit existing equipment). From large-scale infrastructure projects to everyday farm and garden tasks, Naconet™ offers a way to maintain functionality while transitioning to sustainable materials. By deploying Naconet™ in these applications, industries like agriculture, landscaping, construction, and packaging can significantly reduce their plastic footprint without disrupting their processes.

What are the environmental and sustainability benefits of switching to Naconet™?

Adopting Naconet™ compostable netting yields major sustainability benefits compared to sticking with plastic netting.

Here are the key environmental upsides:

- Eliminates Microplastic Pollution: Perhaps the most immediate benefit is stopping the creation of microplastics. Traditional polypropylene netting, when left in the field, will eventually break into tiny plastic fragments that persist in soil and water. Naconet™, by contrast, breaks down completely rather than fragmenting, so it leaves no microplastics behind. This keeps your soil and environment clean. For example, studies have shown PLA-based materials like Naconet™ do not accumulate as persistent microplastics – they continue degrading until fully gone. This is a huge win for ecosystem health, as microplastics from conventional nets have been known to harm soil organisms and even enter water streams.

- Safer for Wildlife and Livestock: Using Naconet™ helps protect wildlife. Leftover plastic netting can ensnare animals (birds, deer, snakes, etc.) even long after use – there are documented cases of birds or snakes fatally trapped in old sod netting. Because Naconet™ gradually softens and disintegrates, there are no synthetic loops or sharp mesh to trap animals once the net’s job is done. This aligns with recommendations from conservation groups (even the U.S. Fish & Wildlife Service encourages using biodegradable options to prevent wildlife entanglement). In farming, if animals like sheep or cattle inadvertently ingest some netting that was on hay, a compostable net is far less harmful than plastic. Overall, you remove a potential hazard from the environment.

- Reduced Carbon Footprint: Naconet™ can significantly lower the carbon footprint of your operations. First, its production uses renewable plant resources, which generally have a smaller carbon footprint than producing polypropylene from petroleum (especially as biopolymer production scales with greener energy). More importantly, the carbon in Naconet™ is biogenic – the plants absorbed CO₂ to make the sugar that becomes PLA. When Naconet™ composts, that CO₂ is released, completing a natural cycle instead of adding new fossil carbon to the atmosphere. In life-cycle assessments, compostable bio-nettings often show better overall LCA results and lower resource utilization compared to fossil plastic netting. Additionally, eliminating the need for removal trips means fewer vehicle runs and less fuel burned in the lifetime of the product. All told, by switching to Naconet™, a company can demonstrably reduce greenhouse gas emissions associated with netting use, helping meet carbon reduction targets.

- Less Landfill Waste: Every roll of plastic netting eventually ends up as waste (if it’s removed). That adds to landfill volume or incineration. With Naconet™, nothing goes to landfill – it turns into compost. This supports a circular economy approach, where materials return to the earth rather than accumulate in dumps. It also eases the burden on waste management systems and complies with emerging waste reduction regulations. If you’re in a region with stringent single-use plastic bans or agricultural waste rules, using a compostable net like Naconet™ keeps you ahead of compliance and reduces waste disposal costs.

- Improves Soil Health: As Naconet™ degrades, it contributes organic matter to soil (much like how mulch or compost does). While the contribution is small, over time this can slightly enrich the soil with humus instead of leaving inert plastic. And since it doesn’t leach harmful substances, it poses no risk to soil quality. In fact, composting standards required testing to ensure the resulting compost is good for plant growth, which Naconet™ passed. Contractors have noted that “compostable nettings provide clean end-of-life, improving soil quality”. No bits of plastic = healthier, cleaner soil for future planting.

- Supports Sustainability Goals and Brand Image: Beyond the physical environmental effects, using Naconet™ sends a powerful message about your commitment to sustainability. If you’re a business (sod farm, produce supplier, land developer, etc.), switching to a compostable product like Naconet™ can help achieve sustainability certifications or meet customer demand for greener practices. Municipalities and companies increasingly prefer suppliers who can demonstrate a reduced environmental impact. By eliminating plastic netting, you can market your product or service as eco-friendly, possibly giving you a competitive edge (e.g. landscapers winning contracts because they offer “plastic-free turf” or produce packagers attracting eco-conscious retailers). You’ll be aligned with global trends (such as the EU Green Deal policies or various states’ plastic restrictions) and positioned as a leader in your industry’s green transition.

In sum, the shift to Naconet™ transforms netting from a source of pollution to a sustainable part of your product lifecycle. You’ll be addressing the very issues that have made plastic netting problematic – from microplastics and wildlife safety to carbon emissions and waste. The benefit is twofold: environmental responsibility and operational practicality. You reduce your carbon and waste footprint, and you do so without sacrificing performance. It’s a rare chance to do what’s right for the planet and improve efficiency (no cleanups, no disposal headaches). For current users of plastic netting who want to minimize their ecological impact, Naconet™ offers a compelling solution that checks all the boxes for sustainability.

Bio-based & compostable netting – discover our sustainable packaging solution

Searching for a sustainable netting for packaging? Our bio-based, compostable nettings deliver unmatched reliability and eco-friendliness - allowing you to maximize efficiency while meeting your environmental goals – means, you’re not loosing any performance with our...

Inside Conwed: Bryan Hofmann on quality, needs & innovation of nettings in erosion control

Ever wondered what it take to build erosion control netting that performs in the toughest conditions? We sat down with one of our industry experts to discuss our innovative approach to netting solutions. Bryan provides insights into the development of products that...

Prepare for the upcoming harvest season- Customized netting solutions for agriculture

Harvest season brings both opportunity and challenge for agricultural operations. While it represents the culmination of months of hard work, it also demands maximum efficiency to protect valuable crops and minimize losses. High-quality agricultural netting has...

Inside Conwed: Dave Gill on needs, trends & innovations in the hay bale market

Ever wondered what sets Conwed apart in the agricultural and hay bale market? We sat down with one of our industry experts to discuss our innovative approach to netting solutions. In the interview, we covered the development and testing of our netting, Conwed’s...

Protective Netting Sleeves for Packaging, Handling, and Processing

Protective netting sleeves have become essential in packaging, handling, and processing environments where product integrity and operational efficiency matter most. When valuable components make their way through complex supply chains or are maneuvered in busy...

Maximizing Agricultural Success with Versatile Netting Solutions

The agricultural landscape today demands durability, adaptability, and innovation. With changing climates, emerging pests, and growing global food demands, farmers, horticulturists, aqua culturists, and land managers need solutions that not only protect their...