Protective Outer Netting: Screens, Sleeves & Rigid Tubes

Filters often need protection and reinforcement on the outside of the media – whether to guard against external damage (like impact or debris) or to add structural integrity under pressure. Conwed offers a variety of extruded netting solutions for outer protection, including flat plastic mesh screens, flexible tubular sleeves, and rigid cylindrical cages/tubes. All are designed to be durable yet lightweight alternatives to metal components like wire mesh wraps or perforated metal cores.

Explore Conwed’s Netting options for Filter Protection:

Protective Screens for Filter Surfaces

Our extruded netting can be used as an outer surfacing mesh on filters – for instance, a plastic mesh layer on the outside of an HVAC filter cartridge or an industrial air intake filter. This mesh serves as a debris screen and stabilization layer. It can stop leaves, insects, or coarse particles from striking the filter media directly, and it helps the filter retain its shape. In air filtration, Conwed square netting applied as an outer wrap protects the pleated media from mechanical strain and prevents fluttering or flexing under variable airflow. Even in outdoor applications (like engine air intakes or HVAC units exposed to the elements), our UV-stabilized polypropylene nets endure sun exposure and weather without degrading. This preserves the filter’s integrity and performance. The rigid structure of the netting additionally “cages” the media, so even as the filter loads up with dust, it remains in form and continues to allow air to pass freely. In summary, a Conwed outer net acts as both armor and skeleton for the filter element – shielding it from external harm and giving it mechanical support.

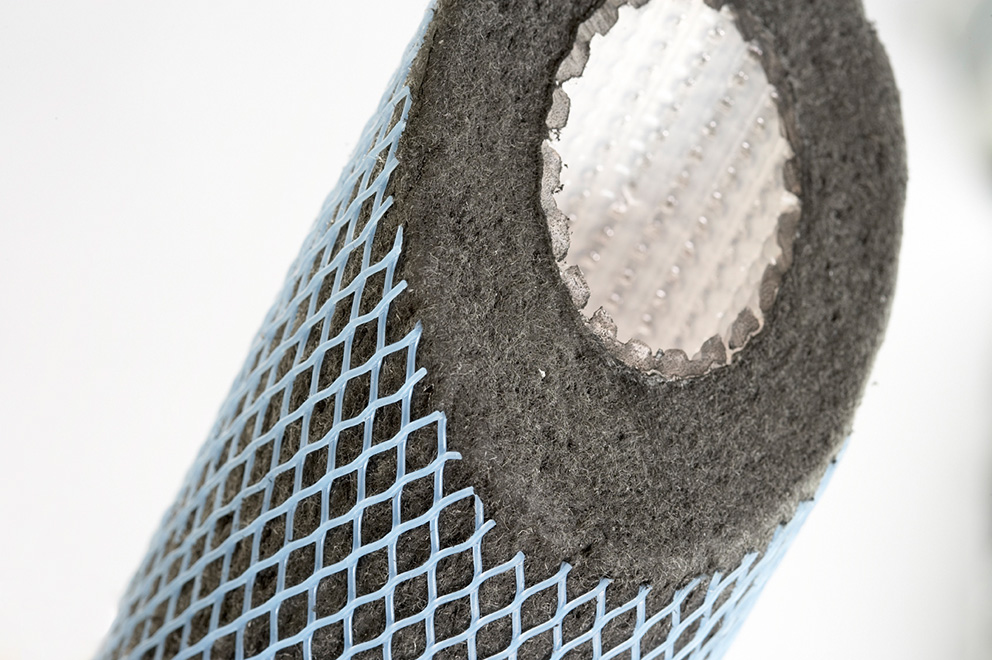

Flexible Mesh Sleeves:

For certain filter designs, a stretchable mesh sleeve is an ideal protective solution. Conwed produces flexible tubular netting (often in a diamond mesh pattern) that can be expanded and slipped over a filter element as a sock or sleeve. These sleeves are elastic and conform to the shape of the filter, whether it’s a cylindrical pleated filter or another cartridge. Once in place, the sleeve gently compresses onto the filter, ensuring it stays put. The purpose of a sleeve is to protect the filter media during handling, installation, and operation. For example, in water filters or industrial cartridges, a sleeve prevents the media (which might be pleated paper or foam) from tearing or gouging when operators insert the filter into housings or when filters knock against each other. It also acts as a pre-filter barrier, catching larger particles (like rust flakes or plant matter) before they hit the media. Conwed’s extruded sleeves are available in different diameters and stretch characteristics; we can supply them in custom cut lengths suitable for single filters. They are an easy retrofit – simply stretch over the filter element – and they add practically no weight. Notably, if more rigidity is needed, a flexible sleeve can be used in combination with a rigid outer cage (sleeve as a inner layer to protect media, cage as outer layer for heavy-duty protection).

Extruded Rigid Tubes and Cores:

When maximum strength and support is required, our extruded cylinder tubes provide a robust solution. Conwed extrudes plastic tubes with an integral square-grid mesh structure (similar to our flat net, but formed as a continuous cylinder) to create rigid filter cores and outer cages. These rigid net tubes are used either at the center of a filter (as a core around which media is wrapped) or around the outside of a filter element (as a protective cage). In liquid filtration like diesel fuel filters or large water filters, a plastic core must withstand internal pressure and keep the filter from collapsing—our extruded cores excel at this, offering high compressive strength with a one-piece, weld-free design. Because they are extruded as a single unit, there are no seams that could split under stress. Compared to a seamed spiral-wound plastic tube or a perforated metal tube, Conwed extruded cores are stronger and more uniformly cylindrical, ensuring even support all around. For outer cages, the extruded rigid tubes act like a durable shell: for instance, in high-pressure water filters, an outer netted cage keeps the pleated media from bowing outward or bursting.

Our extruded rigid tubes (marketed also as Conwed™ Rigid Tubes or Naltex™ Extruded Cages) are rust-proof, non-corrosive, and heat-resistant, making them suitable for demanding environments. They are often used in filters that must be incinerated after use (such as certain chemical or biohazard filters) because they burn to ash without leaving metal remnants. We can customize tube diameter, length, mesh aperture, and thickness to meet any filter design. For example, we produce everything from small-diameter cores for automotive oil filters to large outer cages for industrial bag filters, all with precise and consistent mesh geometry. These tubes can also be produced in different colors or resin types if needed (to match product branding or material specs). By using Conwed rigid nets instead of metal, filter OEMs can simplify their material supply chain (all-polymer construction) and avoid corrosion or contamination issues, while still achieving the required strength and stiffness.

In summary, whether you need a light protective mesh wrap or a beefy structural cage, Conwed has a netting solution: square and diamond nettings that serve as outer wraps and screens, stretchable sleeves for easy-to-apply protection, and extruded rigid tubes that deliver maximum support. These products ensure the filter as a whole is well-protected against mechanical stresses, environmental exposure, and wear-and-tear, thereby safeguarding filtration performance in the field.

Filter Media Solutions

Our sister company GESSNER provides multiple filter media solutions for Transportation & Automotive, Industrial Processes, Air, Water, and Life Science