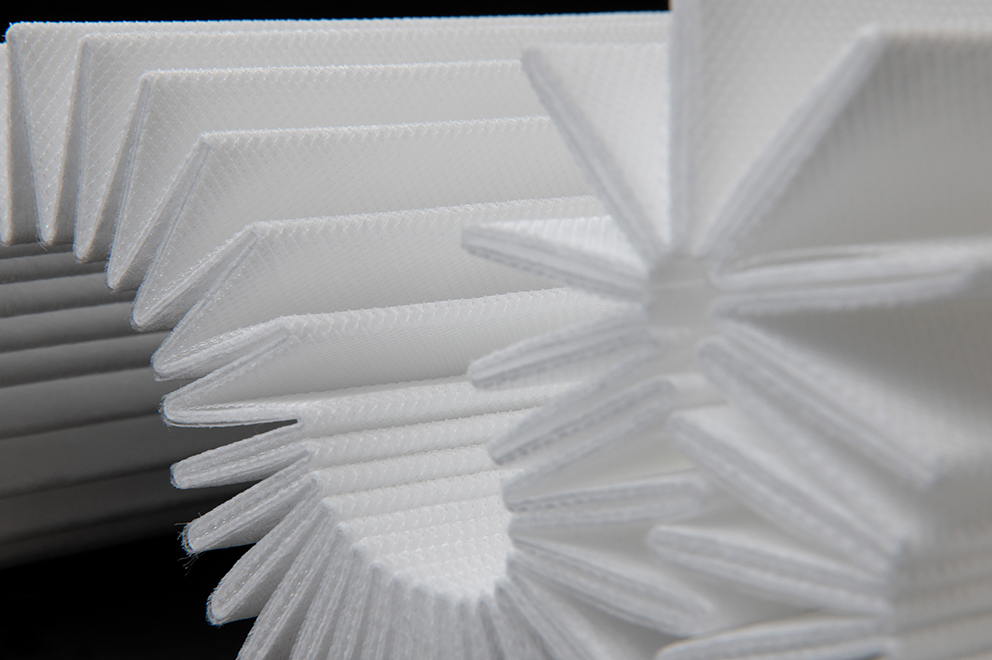

Pleat Support Netting for Air, Oil & Industrial Filters

Pleated filters made of soft, flexible media (such as paper, synthetic fiber, or membranes) rely on support to maintain their shape under airflow or fluid pressure. Conwed’s extruded pleat support netting provides a sturdy lattice structure that supports the filter media and preserves uniform pleat spacing. By keeping pleats evenly separated and preventing them from sagging or sticking together, the netting ensures the entire surface area of the filter is used efficiently for filtration. This leads to lower pressure drop, higher flow rates, and improved filtration performance over the filter’s lifespan.

Our pleat support meshes are more rigid than woven fabrics or nonwovens, yet lightweight. They withstand the force of air or liquid flow, so all pleats remain uniformly exposed to the stream, avoiding collapse when the filter loads with contaminants. In HVAC filtration (e.g. furnace or AC filters) and engine intake or cabin air filters, Conwed netting gives the filter media the structural support it needs to handle high airflow and dust without tearing or deforming. In industrial and hydraulic oil filters, our netting similarly prevents pleat deformation under fluid pressure, even at high temperatures and with exposure to oils, fuels, and chemicals. The plastic netting can be laminated or bonded to the filter media during production, making it easy for filter manufacturers to integrate.

Key Benefits of Conwed Pleat Support Netting:

- Stable, Uniform Pleats: Rigid extruded mesh (often polypropylene or nylon) holds pleats at a fixed spacing, maximizing the effective filtration area and improving efficiency. This also promotes even loading of contaminants across the media.

- Durable & Heat Resistant: We offer high-performance polymers (e.g. polyamide PA6, PBT, polyester, PPS) for pleat supports that require elevated temperature resistance (for example, engine oil or hydraulic filters). These nettings remain stable up to 150+ °C. The plastic mesh is also resistant to chemicals and will not corrode or degrade when in contact with oils, fuels, or aggressive fluids.

- Metal Mesh Replacement: Unlike traditional metal wire mesh supports, our all-plastic netting is non-corroding, lighter weight, and fully incinerable for easier disposal. There are no sharp metal edges, and the product is 100% recyclable polymer, aligning with sustainability goals. Despite being light, the extruded net’s integral joints give it excellent rigidity and mechanical strength.

- Easy Processing: Conwed pleat support nets can be produced in rolls and die-cut or slit to the required size. Their consistent apertures (e.g. common square mesh sizes like 1/4” x 1/4”) and smooth flat profiles facilitate easy pleating, folding, or lamination with filter media. Manufacturers can insert the plastic mesh during filter pleating to form a composite that holds its shape. This integration is seamless and cost-effective, as our extrusion process yields netting that can be tailored in thickness and stiffness as needed.

Overall, Conwed’s pleat support netting keeps filters working at peak efficiency for longer, preventing performance drop-offs due to media collapse or blockage. Proper support also allows filters to be designed with more pleats (higher surface area) without risking crowding or distortion, thereby achieving higher filtration capacity within the same filter dimensions.

Filter Media Solutions

Our sister company GESSNER provides multiple filter media solutions for Transportation & Automotive, Industrial Processes, Air, Water, and Life Science