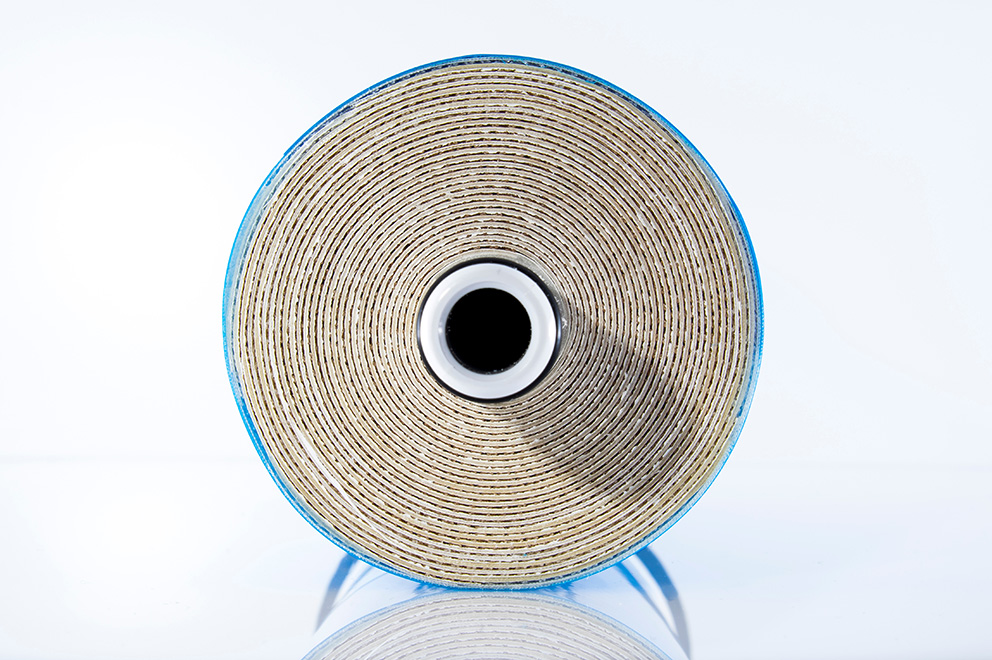

Feed Spacers for Reverse Osmosis & Spiral-Wound Filters

In reverse osmosis (RO) systems and other spiral-wound membrane filters, plastic netting is used as a feed channel spacer between membrane layers. Conwed’s extruded nettings (often in a diamond mesh or patterned square mesh configuration) serve as feed spacers that create consistent flow channels for water or other fluids to pass evenly across the membrane surface. These spacers are critical in RO elements (used for water purification, desalination, etc.) to minimize pressure drop and prevent the flat membrane sheets from pressing together. Our netting maintains a precise gap, allowing feed water to distribute and contact the membrane uniformly, which improves filtration efficiency and throughput.

How Conwed feed spacers enhance RO performance:

- Optimized Flow and Turbulence: The spacer’s mesh geometry is engineered to both facilitate flow and induce slight turbulence in the feed channel. Turbulent flow disrupts boundary layers and reduces fouling; it prevents sediment or biofilm from accumulating in “dead zones.” As a result, the membrane surface stays cleaner for longer, maintaining higher flux. Conwed’s netting has been used as feed spacers that improve fluid dynamics, helping to lower the energy required (reducing pressure requirements) for a given flow rate. For example, our Naltex™ diamond net feed spacers are proven to enhance fluid flow and protect membranes by creating the necessary turbulence while avoiding excessive pressure drop.

- Thin, Durable Profile: We offer spacers in a range of thicknesses (from under 0.5 mm up to several mm) and mesh sizes to suit different RO designs. Bi-planar diamond meshes are a common choice – their two-layer structure and relatively high strand profile keep membranes apart with minimal contact area, which is ideal for RO. We also provide square/rectangular mesh spacers with tailored strand arrangements (e.g. thinner strands in one direction, thicker in the other) as an alternative design for special applications. All our spacers are made via extrusion, yielding an “integral joint” mesh that resists deformation under high pressure. The plastic will not compress or collapse over time, ensuring consistent channel height throughout the filter element’s life.

- Chemical & Temperature Resilience: RO feed spacers often face continuous exposure to water with varying pH, chlorine, or other chemicals, and they may undergo sanitation procedures. Conwed spacers can be made from polypropylene (PP) – a common choice for its chemical resistance in water treatment – or from engineered resins like PVDF or nylon for higher temperature or harsh chemical environments. This allows use in hot water or industrial process filtrations as well as food/beverage or medical fields where compatibility is crucial. The netting materials are FDA-compliant where required (for food/drinking water safety) and will not shed fibers or contaminants.

- Broad Application Range: While reverse osmosis for water purification is a primary use, our feed spacer nets are also used in ultrafiltration and nanofiltration spiral wound elements, as well as in certain dairy and beverage filtration systems that use similar spiral-wound configurations. Almost any thin-film composite (TFC) membrane filter that is spiral-wrapped can benefit from our feed spacers. From household under-sink RO cartridges to large municipal desalination plant modules, Conwed’s spacer technology plays a key role. In fact, nearly all spiral-wound TFC membrane systems (covering home drinking water, wastewater treatment, food & beverage, and even pharma) use this type of plastic net spacer. Our ability to custom-design feed spacers with specific geometries, open areas, and polymer types means we can optimize the spacer for any given system’s requirements (balancing flux, pressure drop, and fouling resistance).

By incorporating Conwed feed spacers, filter manufacturers ensure higher permeate output and longer cleaning intervals for their RO and filtration systems. The end result is more efficient filtration, lower maintenance, and energy savings.

More Solutions for Reverse Osmosis Filter Elements

Our sister company GESSNER provides Membrane Casting Substrates, Machined Parts, and Cores for Reverse Osmosis Filter Elements