Flow channels might not be the first thing that comes to mind when you think about advanced materials, but these engineered pathways are quietly enhancing applications across a wide range of industries. When combined with specialized netting materials, flow channels become powerful tools for managing the movement of air and liquids through composite materials and complex systems.

What Are Flow Channels in Material Composites?

Flow channels are engineered pathways within composite materials that allow controlled movement of fluids—both gases and liquids. These channels serve as highways for air, water, or other substances to travel through otherwise dense or impermeable materials.

In composite manufacturing, flow channels play a critical role during the production process. They allow resin to flow evenly through fiber reinforcements, ensuring complete saturation and eliminating air pockets that could weaken the final product. The channels also facilitate the removal of excess resin and trapped air, resulting in stronger, more consistent composite materials.

Netting Solutions for Air and Liquid Flow Channels

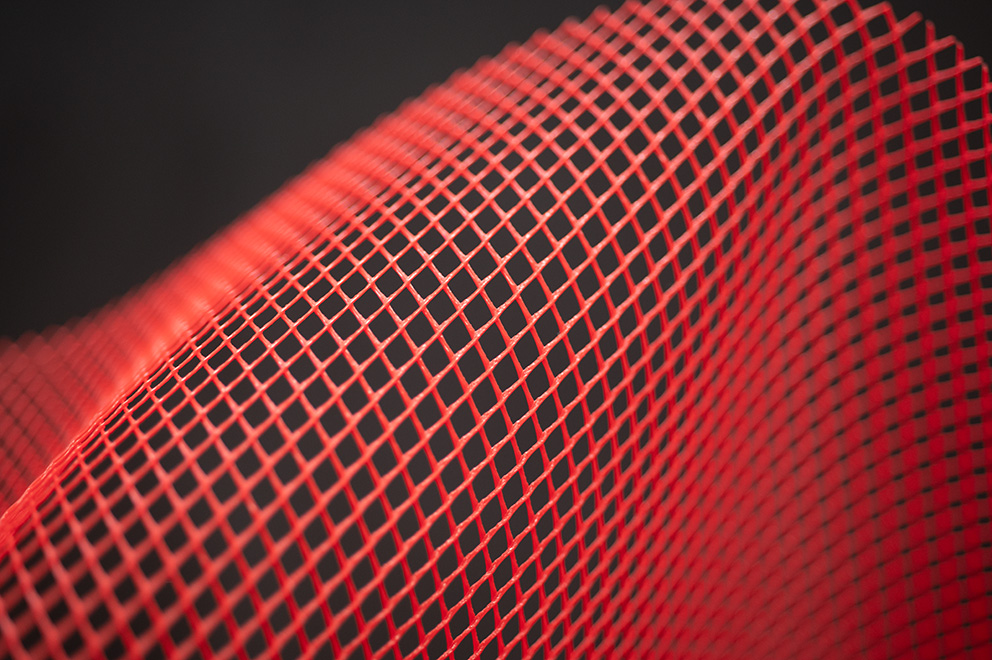

Specialized netting materials have emerged as an elegant solution for creating consistent, reliable flow channels. Unlike rigid channel systems, netting offers flexibility while maintaining structural integrity under various pressure conditions.

Our high-strength plastic netting provides excellent chemical resistance and can be engineered with specific pore sizes to control flow rates. These materials work well in corrosive environments where metal alternatives might fail.

For composite materials we provide an optional adhesive coating to streamline production processes and enhance efficiency.

Design Considerations

The effectiveness of netting in flow channel applications depends on several key factors:

- Mesh Size: The opening size determines flow rate and filtration capability. Smaller openings provide better filtration but may restrict flow, while larger openings allow higher flow rates but less particle retention. Different weaving patterns affect both flow characteristics and mechanical properties. Some patterns optimize laminar flow, while others enhance turbulent mixing.

- Material Thickness: Thickness is a controllable variable where engineers can balance structural requirements and needs with flow performance to optimize their product design. Thickness can be increased or decreased to allow or limit certain size particles to flow through the composite. It can also be modified to increase or decrease the flow rate aiding product performance.

That is why we offer a wide range of flow channel nettings to fit specific needs of each application. For unique applications and requirements, we are able to customize our nets to meet even the most demanding challenges.

Benefits of our Conwed netting in flow channels

Slurry Filtration Advantages

One of the most significant benefits of netted flow channels is their ability to handle slurry filtration effectively. Traditional filtration systems often struggle with particle-laden liquids that can clog conventional filters or create uneven flow patterns.

Netting-based flow channels address these challenges by:

- Maintaining Consistent Flow: The three-dimensional structure of netting prevents complete blockage, allowing continued flow even when some particles accumulate.

- Self-Cleaning Action: The turbulent flow created by netting helps prevent particle buildup, reducing maintenance requirements and extending operational life.

Air Flow Mitigation

Air flow management represents another critical application area. Netted flow channels excel at controlling air movement in ways that solid channels cannot match.

- Pressure Distribution: Netting helps distribute air pressure more evenly across surfaces, preventing localized stress concentrations that could damage sensitive materials or structures.

- Turbulence Control: Strategic netting placement can either promote mixing through controlled turbulence or maintain laminar flow conditions, depending on application requirements.

- Temperature Management: Air flow through netted channels can be optimized for heat transfer, helping manage temperature in everything from electronic components to building HVAC systems.

Lightweight and Low Cost

Netting offers significant advantages by being both lightweight and cost-effective. While its material contribution to a composite may be minimal, its role is essential in enhancing the overall performance and efficiency of the entire composite system. This makes it an indispensable element in applications where weight reduction and budget constraints are priorities. By maximizing material efficiency without adding considerable expense, netting provides a practical and innovative solution in various industries.

Consistent manufacturing quality

Another significant benefit of Conwed netting is its consistency in manufacturing. By maintaining strict control over the production process, we ensure that the netting meets precise quality standards, minimizing potential issues during usage. This consistency translates to improved reliability, allowing industries to depend on the netting for critical applications without interruptions or defects. The ability to deliver uniform products not only optimizes performance but also reduces downtime and costs associated with product inconsistencies.

Applications Across Industries

Netted flow channels offer versatile solutions across various industries, enhancing moisture and air management, process efficiency, and product quality.

Filtration applications greatly benefit from the engineered flow channel netting, which is ensuring optimal performance. It enhances fluid distribution, prevents clogging, and guarantee consistent flow by creating structured pathways for liquids to pass through. This improves filtration efficiency, reduces maintenance, and extends the lifespan of the filtration system.

In construction, flow channel nettings can wick moisture away from wall or roofs, improve ventilation, provide structural support to media and boost insulation performance. Other specialized uses include water treatment, food processing, and pharmaceutical production, ensuring precise flow control.

Optimizing Performance Through Design

Success with flow channels requires careful attention to design details. Flow modeling and testing help optimize netting selection and channel geometry for specific applications.

Future developments in netting materials and manufacturing techniques promise even greater capabilities. Smart materials that respond to environmental conditions, bio-compatible netting for medical applications, and enhanced durability for extreme environments represent just a few areas of ongoing advancement.

From simple filtration to complex multi-phase flow management, we offer flow channel nettings that traditional rigid channels simply cannot match. Get in touch with us to find a netting that perfectly fits your needs.